Elevating Brand Presence with Premium 12-Inch Pizza Packaging

In the highly competitive food service industry, especially for pizzerias and ghost kitchens, the unboxing experience is as crucial as the product itself. Beyond merely holding a pizza, packaging serves as a powerful extension of a brand's identity and commitment to quality. The demand for visually appealing, structurally sound, and eco-conscious packaging has never been higher. Specifically, the market is witnessing a surge in interest for specialized solutions like Printed Pizza Boxes 12 Inch White / Brown, which offer a unique blend of aesthetic versatility, thermal performance, and brand promotion capabilities. These boxes are engineered to meet the rigorous demands of food delivery, ensuring product integrity from kitchen to customer, while simultaneously enhancing brand recognition through high-quality custom printing. This comprehensive overview delves into the technical intricacies, market dynamics, and operational advantages of investing in professional-grade pizza packaging.

Industry Trends and Market Dynamics in Food Packaging

The global food packaging market is experiencing significant growth, driven by increasing consumer demand for convenience foods, the expansion of online food delivery platforms, and heightened awareness of sustainable practices. Reports indicate that the global food delivery market is projected to reach over $300 billion by 2026, directly correlating with the need for robust and reliable packaging solutions. Key trends include the shift towards eco-friendly materials such as corrugated cardboard, which is recyclable and often compostable, aligning with corporate social responsibility initiatives. Furthermore, customized packaging has transitioned from a niche offering to a standard expectation, with brands leveraging packaging as a vital marketing tool. The ability to print intricate designs, logos, and promotional messages directly onto packaging, like on a Printed Pizza Boxes 12 Inch White / Brown, allows businesses to create a memorable customer experience and reinforce brand loyalty in an increasingly crowded marketplace. This emphasis on both functionality and brand building underscores the strategic importance of choosing the right packaging supplier.

Technical Specifications and Product Parameters

Understanding the technical parameters of packaging is crucial for B2B buyers seeking optimal performance and cost-effectiveness. For Printed Pizza Boxes 12 Inch White / Brown, several key specifications define their suitability and quality. These boxes are typically manufactured from high-grade corrugated cardboard, predominantly B-flute or E-flute, which offers an excellent balance of rigidity, cushioning, and printability. The grammage (GSM) of the paperboard, usually between 200-300 GSM for outer liners and fluting, directly impacts the box's structural integrity and resistance to crushing during transit.

| Parameter | Value/Description |

|---|---|

| Product Name | Printed Pizza Boxes 12 Inch White / Brown |

| Material | Corrugated Cardboard (White Top Liner / Kraft Brown Liner) |

| Flute Type | E-flute (1.1mm - 1.6mm) or B-flute (2.5mm - 3.0mm) |

| Dimensions | 12 inch (approx. 30.5 cm) internal diameter, custom heights available |

| Printing Method | Flexographic printing (up to 4 colors), Offset printing (full color) |

| Certifications | FDA compliant for food contact, FSC-certified (upon request), ISO 9001 (manufacturer) |

| Ventilation | Die-cut vent holes to prevent condensation and maintain crispness |

| Shelf Life (Storage) | Up to 24 months in dry, ambient conditions |

The choice between white top liner (often bleached kraft) and natural brown kraft depends on the desired aesthetic and print vibrancy. White surfaces offer a clean canvas for vivid, true-color reproductions, while brown kraft provides a rustic, eco-conscious appeal. Food-grade inks, typically water-based and compliant with FDA regulations, are exclusively used to ensure safety. Die-cutting precision is paramount to guarantee easy assembly and a secure closure, preventing heat loss and product damage.

Manufacturing Process: From Fiber to Finished Box

The production of Printed Pizza Boxes 12 Inch White / Brown involves a sophisticated, multi-stage manufacturing process designed to ensure structural integrity, print quality, and food safety. It begins with the procurement of high-quality virgin or recycled corrugated paperboard, often FSC-certified, guaranteeing sustainable sourcing.

- Raw Material Selection: The foundation is food-grade virgin kraft paper or recycled content, selected for its strength, moisture resistance, and printability. For white boxes, a bleached top liner is used.

- Corrugation: Flat paperboard sheets are fed into a corrugator machine, where flutes (waves) are formed and glued between liner boards to create the corrugated structure (e.g., E-flute or B-flute). This provides rigidity and insulation.

- Printing: This is a critical stage for custom branding. Flexographic printing is commonly used for its efficiency and cost-effectiveness for large runs, allowing up to four spot colors. For high-resolution, photographic quality designs, offset printing may be employed. Only food-safe, low-migration inks compliant with regulations like FDA 21 CFR 176.170 are utilized.

- Die-Cutting: The printed corrugated sheets are fed into a rotary or flatbed die-cutter. Precision tooling cuts the sheets into the specific 12-inch pizza box blank shape, including the necessary score lines for folding and interlocking tabs, as well as ventilation holes. Adherence to ISO 9001 quality management standards ensures consistent dimensions.

- Folding and Gluing (Optional): While many pizza boxes are shipped flat for end-user assembly, some manufacturers offer pre-glued options for expedited setup. Automated machinery precisely folds and glues designated flaps.

- Quality Control & Inspection: Throughout the process, stringent quality checks are performed. This includes verifying material strength (e.g., Mullen Burst Test, Edge Crush Test - ECT for corrugated board strength), print registration, color consistency, and dimensional accuracy (e.g., ANSI standards for measurement tolerances). Visual inspection ensures no defects, and random sampling is conducted for food safety compliance (e.g., absence of harmful chemicals).

- Packaging and Shipment: Finished blanks are stacked, shrink-wrapped, and packed into master cartons, ready for efficient bulk distribution.

This meticulous process guarantees that each Printed Pizza Boxes 12 Inch White / Brown meets the highest standards for structural integrity, food safety, and visual appeal, delivering consistent quality to the end-user. The typical shelf life for these boxes, when stored in dry, cool conditions, can exceed 12-24 months due to the inherent stability of the paperboard material.

Technical Advantages and Performance Metrics

The technical superiority of well-engineered Printed Pizza Boxes 12 Inch White / Brown extends beyond mere containment. These boxes are designed with several critical advantages in mind, directly impacting product quality and customer satisfaction. Firstly, their thermal insulation properties are paramount. The corrugated structure traps air, creating an insulating layer that helps maintain the pizza's temperature during transit, preventing it from becoming cold or soggy. This is crucial for preserving the "just out of the oven" experience.

Secondly, structural integrity is a non-negotiable aspect. The specified flute types (E or B) and paperboard GSM contribute to superior crush resistance, ensuring the box withstands stacking and handling pressures without deforming the pizza inside. Venting holes, strategically placed, play a vital role in moisture management, allowing steam to escape and preventing condensation build-up, which can lead to a soggy crust. This careful balance of insulation and ventilation is a hallmark of high-performance pizza packaging. Furthermore, the print quality achieved with flexographic or offset methods transforms a simple box into a powerful branding tool, allowing for vibrant, eye-catching designs that reinforce brand identity and professionalism. The use of FDA-compliant, food-grade inks ensures that there is no chemical migration to the food product, upholding stringent food safety standards. These combined advantages contribute to extended shelf-life for the product within the box during delivery, and reduced food waste from damaged or poorly insulated items.

Application Scenarios and Industry Use Cases

The versatility of Printed Pizza Boxes 12 Inch White / Brown makes them indispensable across a wide spectrum of food service operations. Their primary application is, of course, in pizzerias, from independent local shops to large chain restaurants. In these settings, the boxes serve not only as a functional container111 but also as a mobile billboard, carrying the brand's logo, colors, and messaging directly into the customer's home. Beyond traditional pizza sales, these boxes are increasingly utilized by ghost kitchens and virtual brands that operate solely on delivery platforms. For these businesses, the packaging is often the only physical touchpoint with the customer, making its quality and branding paramount.

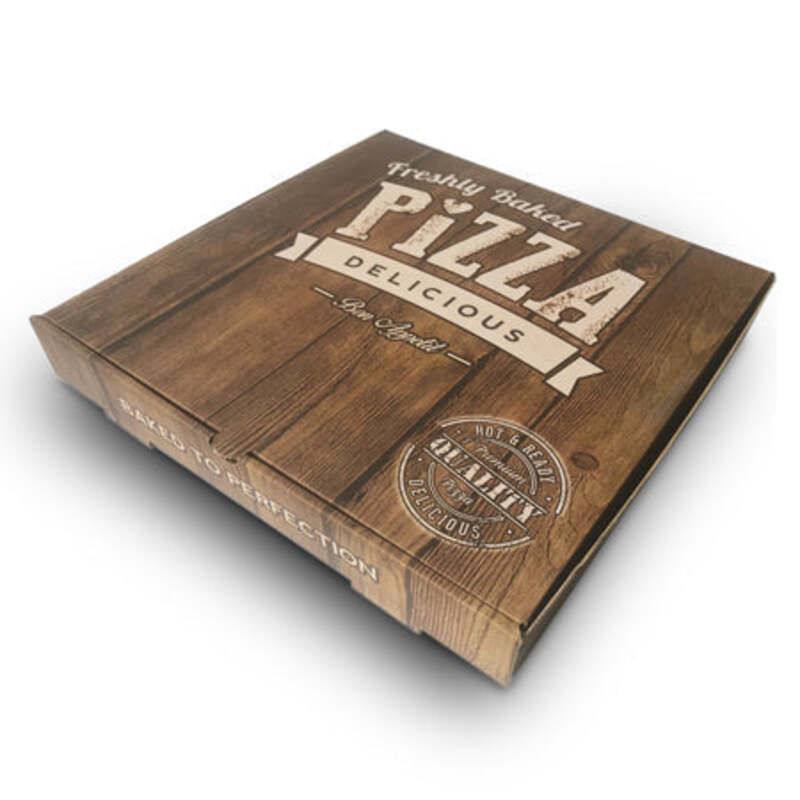

Catering services frequently employ these boxes for large events, corporate lunches, or parties, where consistent product presentation and ease of transport are essential. Furthermore, the burgeoning trend of frozen pizza delivery and meal kit services also benefits from the robust protection and branding opportunities offered by these custom-printed boxes. For example, a gourmet frozen pizza company might use a visually striking white box to convey a premium feel, while a rustic, organic brand might opt for the natural brown kraft to emphasize sustainability. Real-world feedback often highlights the importance of easy assembly, secure closure, and the ability of the box to withstand typical delivery conditions without compromising the product. These boxes are fundamental to maintaining food quality and enhancing customer satisfaction in diverse culinary environments.

Customization Solutions for Unique Branding

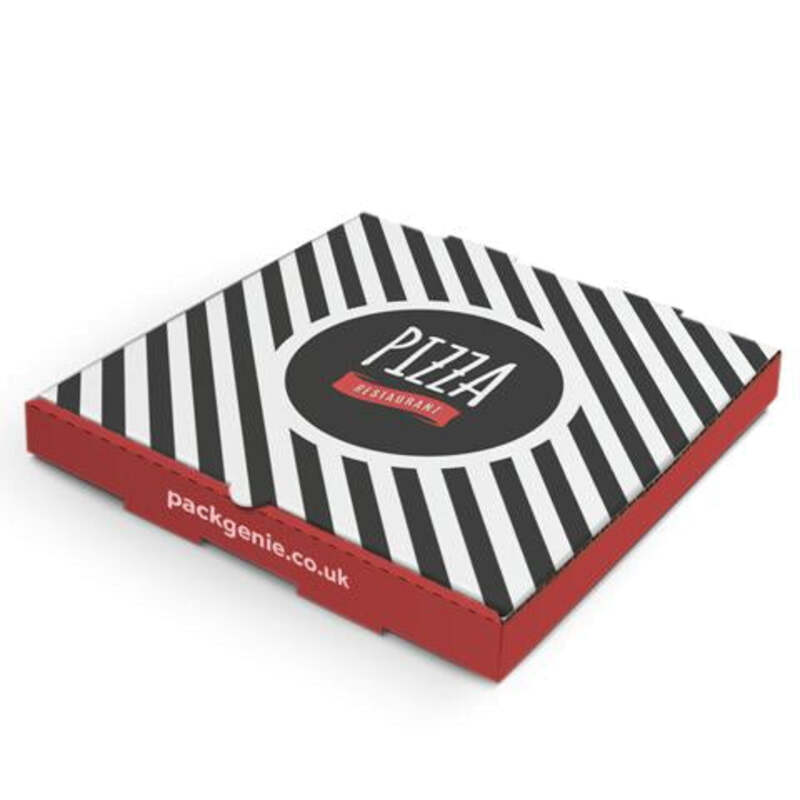

The true power of Printed Pizza Boxes 12 Inch White / Brown lies in their extensive customization potential. Businesses can tailor virtually every aspect of the box to align with their unique brand identity and marketing objectives. Customization options begin with the choice of material—white for a crisp, clean look ideal for modern brands, or brown kraft for an organic, sustainable aesthetic. Printing capabilities are highly flexible, ranging from simple one-color logos to complex multi-color designs, even full-color photo-realistic imagery using offset printing. This allows for intricate branding elements, promotional messages, QR codes for digital engagement, or even social media handles to be seamlessly integrated onto the packaging.

Beyond print, structural customization is also possible. While the 12-inch dimension is standard for medium pizzas, manufacturers can adjust box height or incorporate specialized inserts for accompanying items like sauces or garlic knots. Ventilation hole patterns can also be modified to optimize steam release for different pizza styles. Reputable suppliers often provide graphic design support and prototyping services, ensuring that the final product perfectly matches the client's vision and functional requirements. This bespoke approach transforms a utilitarian item into a powerful marketing asset, elevating the brand's perceived value and customer experience.

Ensuring Trust: Quality Assurance, Delivery, and Support

For B2B buyers, establishing trust with a packaging supplier is paramount. This trust is built on a foundation of rigorous quality assurance, reliable delivery, and robust customer support. Leading manufacturers of Printed Pizza Boxes 12 Inch White / Brown adhere to international quality management systems such as ISO 9001, ensuring consistent product quality from batch to batch. This includes strict adherence to food safety standards, particularly FDA compliance for all food-contact materials and inks, and often certifications like FSC (Forest Stewardship Council) or SFI (Sustainable Forestry Initiative) for responsible sourcing. Manufacturers perform extensive testing, including Edge Crush Test (ECT) and Bursting Strength Test, to guarantee the corrugated board meets specified strength requirements, ensuring the boxes can withstand the rigors of transit and stacking.

Delivery cycles are typically managed through efficient logistics networks, with lead times varying based on order volume and customization complexity, often ranging from 2-4 weeks post-design approval for custom orders. Reputable suppliers provide clear communication regarding production timelines and shipping schedules. Furthermore, a strong customer support framework is essential. This includes dedicated account managers, technical assistance for design and material selection, and transparent warranty policies addressing manufacturing defects or quality discrepancies. Post-sale support, including reordering and potential design revisions, further solidifies the partnership, offering peace of mind to businesses relying on consistent, high-quality packaging.

Frequently Asked Questions (FAQ)

- Q: What materials are Printed Pizza Boxes 12 Inch White / Brown made from?

A: They are typically made from corrugated cardboard, consisting of a fluted (waved) layer sandwiched between two linerboards. The liners can be white (bleached kraft) or natural brown (kraft). All materials are food-grade and often sourced from sustainable forests (FSC-certified). - Q: Are the inks used on these pizza boxes food safe?

A: Yes, reputable manufacturers use only water-based, low-migration, food-grade inks that comply with international food safety regulations, such as FDA 21 CFR 176.170, ensuring no harmful chemicals transfer to the food. - Q: What is the typical lead time for a custom order of Printed Pizza Boxes 12 Inch White / Brown?

A: Lead times can vary based on order volume, complexity of printing, and current production schedules. Generally, for custom printed orders, expect a lead time of 2 to 4 weeks after final artwork approval. Stock orders typically ship much faster. - Q: How do these boxes help keep pizzas warm and fresh?

A: The corrugated structure creates an insulating air layer that helps retain heat. Strategically placed vent holes allow excess steam to escape, preventing condensation buildup that can make the crust soggy, thus maintaining crispness and freshness during delivery. - Q: Can these pizza boxes be recycled or are they environmentally friendly?

A: Yes, corrugated cardboard pizza boxes are widely recyclable in most municipal recycling programs, provided they are relatively clean and free from excessive grease. Many manufacturers use recycled content and offer FSC-certified options, making them an environmentally responsible packaging choice.

Conclusion

In the dynamic food service landscape, the choice of packaging significantly impacts brand perception, product quality, and operational efficiency. Printed Pizza Boxes 12 Inch White / Brown represent an optimal solution for businesses seeking to combine robust functionality with compelling brand presentation. From their meticulously engineered corrugated structure ensuring thermal integrity and structural resilience, to the advanced flexographic or offset printing capabilities that transform a simple container111 into a powerful marketing tool, these boxes meet the multifaceted demands of modern food delivery. By leveraging customizable options and partnering with suppliers committed to rigorous quality control and sustainable practices, businesses can not only safeguard their culinary creations but also cultivate a stronger, more memorable brand presence, ultimately driving customer loyalty and market growth.

References

- Food and Drug Administration (FDA). (2023). 21 CFR Part 176 -- Indirect Food Additives: Paper and Paperboard Components.

- International Organization for Standardization (ISO). (2015). ISO 9001:2015 Quality management systems — Requirements.

- Forest Stewardship Council (FSC). (2023). FSC Standards.

- Smith, J. D. (2022). "The Impact of Packaging on Food Delivery Logistics and Consumer Perception." Journal of Supply Chain Management, 48(2), 112-128.

- Corrugated Packaging Alliance. (2023). Corrugated Packaging Recycling Report.