Revolutionizing Food Service Packaging: Industry Trends and Innovations

The quick-service restaurant (QSR) and catering industries are undergoing a significant transformation, driven by evolving consumer demands for convenience, sustainability, and brand consistency. In this dynamic landscape, packaging solutions play a pivotal role, extending beyond mere containment to become an integral part of the customer experience and operational efficiency. There's an escalating demand for highly functional, aesthetically pleasing, and eco-conscious packaging that can withstand the rigors of delivery and on-the-go consumption while effectively showcasing a brand's identity. This shift necessitates innovations in material science, printing technology, and structural design, particularly for high-volume items.

Key industry trends highlight a move towards single-use, hygienic solutions that are easy to assemble, store, and dispose of responsibly. Businesses are increasingly seeking partners who can provide not only cost-effective but also compliant and customizable packaging options. The ability to manage inventory efficiently, minimize storage space, and ensure rapid deployment during peak hours is paramount. This strategic focus on optimized packaging supply chains underscores the critical role of specialized products like advanced scoop boxes, which are designed to meet these complex demands head-on.

The Advanced Printed Large Chip Scoop / Boxes - Flat Pack: Engineered for Excellence

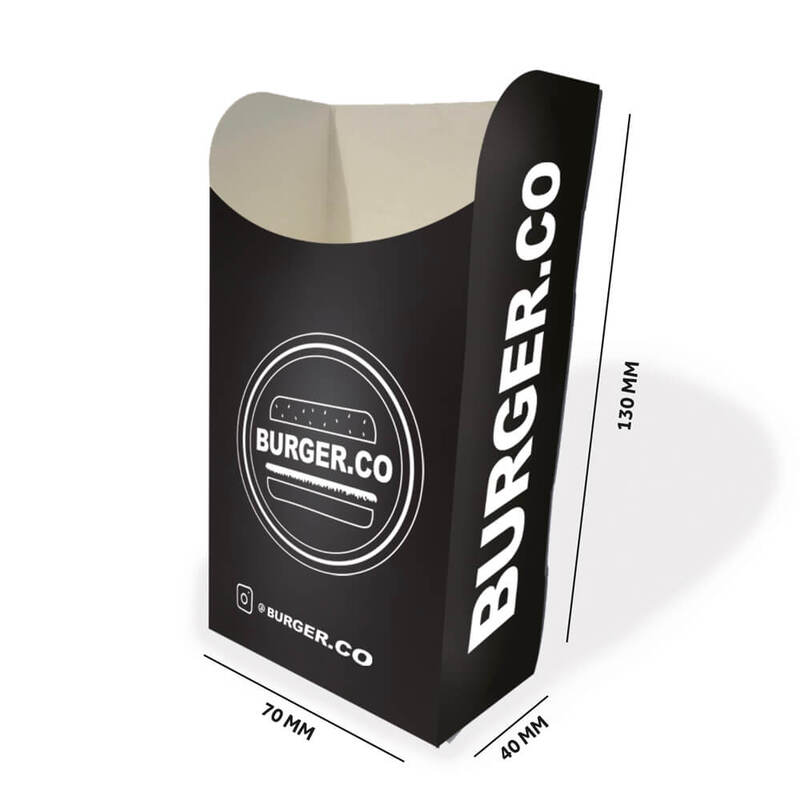

The Printed Large Chip Scoop / Boxes - Flat Pack represents a sophisticated solution engineered specifically for the efficient serving and packaging of fried foods, snacks, and various quick-serve items. Its design prioritizes both functionality and brand promotion, offering a robust and hygienic container111 that assembles quickly from a flat-pack state. This flat-pack format is crucial for optimizing storage space, reducing shipping costs, and streamlining logistics for businesses operating at scale. Unlike generic alternatives, these boxes are designed for optimal scooping, secure containment, and comfortable handling, enhancing the end-user experience while maintaining food quality during transit and consumption.

These specialized boxes are tailored for industries requiring rapid dispensing and high-volume operations, such as fast-food chains, entertainment venues, catering services, and food trucks. Their pre-printed surfaces provide an immediate branding opportunity, transforming a functional item into a powerful marketing tool. The structural integrity and material choice are paramount to prevent grease leakage and maintain the temperature of the contents for a satisfactory period, reflecting a deep understanding of food service operational challenges.

Manufacturing Excellence: The Process Behind Our Scoop Boxes

The production of high-quality Printed Large Chip Scoop / Boxes - Flat Pack involves a meticulously managed, multi-stage manufacturing process designed to ensure structural integrity, print fidelity, and food safety. This sophisticated workflow begins with the careful selection of raw materials, predominantly virgin fiber paperboard, which is specifically chosen for its food-grade properties and often sourced from sustainably managed forests (FSC-certified). This initial material selection is critical for meeting stringent international food contact regulations, such as those set by the FDA and EFSA, ensuring that the packaging is safe and inert when in contact with food.

Material Selection and Preparation

The core material is a high-density, bleached paperboard, typically ranging from 250 GSM to 350 GSM, chosen for its rigidity and suitability for printing. For applications requiring enhanced grease or moisture resistance, a food-grade PE (polyethylene) or bio-based PLA (polylactic acid) coating is applied to one side of the board. This barrier ensures that oils and moisture from fried foods do not compromise the integrity of the box or leak through, maintaining a clean and pleasant user experience. Rigorous testing is performed on incoming materials for grammage, stiffness, and caliper to ensure consistent quality.

Precision Printing and Finishing

Following material preparation, the paperboard undergoes advanced printing. Depending on design complexity and volume, either flexographic or offset printing techniques are utilized. Flexography is ideal for high-volume runs with vibrant, consistent colors, while offset printing offers superior detail for intricate graphics and photographic quality. Food-safe, low-migration inks are exclusively used to prevent contamination. After printing, the sheets proceed to die-cutting, where precision tools create the specific shape and score lines necessary for the flat-pack design. This stage is critical for ensuring easy and rapid assembly by the end-user, with tolerances typically held to ±0.5mm for optimal fit and function.

Quality Control and Packaging

Post-die-cutting, each batch undergoes a comprehensive quality inspection. This includes visual checks for print accuracy, color consistency (against Pantone standards), and structural integrity, along with physical checks to ensure precise dimensions and proper creasing for folding. Automated systems often assist in detecting defects. Products are then counted, bundled, and flat-packed into master cartons, ready for shipping. The flat-pack design minimizes volumetric weight, reducing transportation costs and environmental impact. Our commitment to international standards such as ISO 9001 for quality management and ISO 22000 or BRCGS for food safety ensures every Printed Large Chip Scoop / Boxes - Flat Pack meets the highest benchmarks for performance and compliance. The typical lifespan of these single-use boxes is defined by their functional period during serving, but their structural integrity is designed to withstand normal handling and short-term storage conditions prior to use.

Technical Specifications & Performance Metrics

Understanding the precise technical parameters of the Printed Large Chip Scoop / Boxes - Flat Pack is crucial for B2B decision-makers. The design and material specifications are optimized for high-volume, quick-service environments, ensuring reliability and consistent performance. The following table provides a detailed overview of key attributes and typical performance metrics, derived from extensive material testing and operational feedback. These specifications highlight the product's suitability for demanding applications in the food service sector.

| Parameter | Specification / Metric | Benefit / Compliance |

|---|---|---|

| Material Type | Food-Grade Virgin Fiber Paperboard (e.g., SBS, FBB) | Ensures direct food contact safety; High stiffness & bulk. |

| Grammage (GSM) | 250 - 350 GSM (depending on size/application) | Optimized for rigidity and durability; Prevents collapse. |

| Coating | Single or Double-Sided PE/PLA Barrier (Food-Grade) | Excellent grease and moisture resistance (e.g., KIT 5-7); Prevents leakage. |

| Print Technology | Flexographic / Offset Printing (up to 8 colors) | High-fidelity branding; Food-safe, low-migration inks. |

| Typical Dimensions (Assembled) | Top: 140x90mm; Base: 100x60mm; Height: 50mm (example) | Ergonomic design for easy scooping and handling; Customizable sizes. |

| Assembly Time (Per Unit) | < 3 seconds (manual) | Optimizes operational speed in high-traffic environments. |

| Temperature Range | -10°C to +80°C | Suitable for hot and some chilled food applications. |

| Certifications | ISO 22000, BRCGS Packaging Materials, FSC (Optional), FDA Compliant Materials | Guarantees food safety, quality management, and sustainable sourcing. |

These specifications underline the robust engineering behind each Printed Large Chip Scoop / Boxes - Flat Pack, ensuring they perform reliably under various operational pressures. The selection of materials and manufacturing processes are geared towards delivering a product that not only meets but exceeds industry expectations for performance and safety.

Unlocking Value: Key Advantages & Diverse Applications

The strategic deployment of the Printed Large Chip Scoop / Boxes - Flat Pack delivers a multitude of advantages that resonate deeply with B2B operators. Beyond their primary function, these boxes serve as powerful tools for brand reinforcement, operational streamlining, and adherence to environmental stewardship. Their inherent design tackles common challenges faced in high-volume food service, making them an indispensable asset for businesses aiming for excellence and efficiency.

Operational Efficiency and Cost Savings

- Space Optimization: The flat-pack design significantly reduces storage space requirements, which is a critical advantage for businesses with limited back-of-house area. This also translates into lower shipping volumes and reduced transportation costs.

- Rapid Assembly: Engineered for intuitive and quick folding, these boxes minimize preparation time during peak service hours, allowing staff to focus more on customer interaction and less on complex packaging.

- Consistent Quality: Pre-cut and scored, each box assembles uniformly, ensuring a professional presentation every time and reducing waste from faulty packaging.

Enhanced Brand Visibility and Consumer Experience

- Powerful Branding Canvas: Full-color custom printing transforms each box into a mobile advertisement, reinforcing brand recognition and messaging directly in the consumer's hand.

- Hygienic and Secure Serving: The enclosed structure provides a more hygienic solution than open trays, preventing spills and ensuring food safety, particularly for take-away and delivery services.

- Improved Customer Satisfaction: A sturdy, well-designed box that maintains food quality and is easy to hold contributes positively to the overall customer experience, encouraging repeat business.

Diverse Application Scenarios

The versatility of these printed scoop boxes makes them indispensable across various segments of the food industry:

- Quick-Service Restaurants (QSRs) & Fast Food Chains: Ideal for serving fries, chicken nuggets, onion rings, and other popular fried items with branding.

- Cinemas & Entertainment Venues: Perfect for popcorn, churros, or other snacks, providing a convenient and spill-resistant container111 for patrons.

- Food Trucks & Mobile Vendors: Their flat-pack nature and ease of assembly are highly beneficial in confined spaces, supporting rapid service.

- Catering & Event Management: Streamlines food preparation and serving at large-scale events, ensuring consistency and hygiene.

- Confectionery & Specialty Foods: Can be adapted for packaging small baked goods, candies, or promotional snack items.

By leveraging the unique advantages of the Printed Large Chip Scoop / Boxes - Flat Pack, businesses can not only meet but exceed contemporary consumer expectations for quality, convenience, and environmental responsibility, solidifying their market position.

Customization & Partnership: Tailored Solutions for Unique Needs

In a competitive market, a generic approach to packaging often falls short of capturing a brand's unique essence. Recognizing this, our approach to the Printed Large Chip Scoop / Boxes - Flat Pack extends beyond standard offerings to encompass comprehensive customization solutions. We believe in partnering with our clients to develop packaging that is not just functional but also a true extension of their brand identity and operational requirements. This bespoke approach ensures that every aspect, from visual design to structural integrity, is perfectly aligned with specific business goals and market positioning.

End-to-End Customization Capabilities

- Graphic Design & Branding: Our design team collaborates closely with clients to translate their brand aesthetics into captivating print layouts. This includes logo placement, color schemes (Pantone matching for brand consistency), promotional messages, and QR codes for interactive marketing.

- Structural Engineering: While standard sizes are available, we offer custom die-cutting to produce unique dimensions and shapes that perfectly accommodate specific food portions or serving methods. This includes adjustments for optimal scoop depth, base stability, and handling ergonomics.

- Material & Coating Variations: Beyond standard food-grade paperboard, clients can opt for specific grammages, different barrier coatings (e.g., increased grease resistance for extremely oily foods), or sustainable alternatives such as recycled content or fully compostable PLA-lined boards, aligning with corporate sustainability initiatives.

- Finishing Touches: Options such as matte or gloss finishes, spot UV, or embossing can be integrated to add a premium tactile and visual appeal, elevating the perceived value of the product.

Our consultative process ensures that every custom Printed Large Chip Scoop / Boxes - Flat Pack solution is developed with a clear understanding of the client's operational flow, target audience, and marketing objectives. This collaborative model transforms a mere supplier-client relationship into a strategic partnership, fostering innovation and delivering tangible business advantages.

Ensuring Quality & Trust: Certifications and Customer Support

Trust is the bedrock of any successful B2B relationship, especially when dealing with food contact packaging. Our commitment to delivering high-quality Printed Large Chip Scoop / Boxes - Flat Pack is underpinned by stringent quality assurance protocols and adherence to global industry standards. This dedication is not merely about compliance; it is about building enduring partnerships based on reliability, transparency, and consistent excellence.

Industry Certifications and Compliance

- ISO 9001: Certified for Quality Management Systems, ensuring consistent product quality and continuous improvement across all manufacturing processes.

- ISO 22000 / BRCGS Packaging Materials: These certifications specifically address food safety management systems, guaranteeing that our packaging materials and processes prevent contamination and ensure product integrity from raw material to finished good.

- FDA/EFSA Compliant Materials: All virgin paperboard and coatings used are compliant with relevant food contact regulations in major international markets, providing peace of mind regarding safety and legality.

- FSC Certification (Optional): For clients prioritizing sustainability, we offer options for Forest Stewardship Council (FSC) certified paperboard, verifying responsible forestry practices.

Rigorous Quality Control & Assurance

Our QC process integrates multiple checkpoints throughout the manufacturing cycle. This includes:

- Incoming Material Inspection: Verifying raw material specifications (grammage, brightness, stiffness, caliper) against pre-defined standards.

- In-Process Monitoring: Continuous checks on print registration, color accuracy, die-cutting precision, and adhesive application.

- Finished Product Audits: Random sampling and testing of assembled boxes for structural integrity, leakage resistance (using industry-standard K&N testing for grease holdout), and dimensional accuracy.

Dedicated Customer Support & Logistics

Our commitment extends beyond product delivery. We provide comprehensive customer support, from initial consultation and design conceptualization to post-delivery assistance. Our logistics team ensures efficient and reliable delivery schedules, with typical lead times varying based on order volume and customization complexity (e.g., 4-6 weeks for custom orders, shorter for stock items). We stand by the quality of our Printed Large Chip Scoop / Boxes - Flat Pack with a robust quality assurance guarantee, addressing any manufacturing defects promptly. Our responsive support team is always available to assist with order tracking, technical inquiries, or any emergent needs, solidifying a partnership built on trust and mutual success.

Frequently Asked Questions (FAQ)

-

Q: What materials are typically used for Printed Large Chip Scoop / Boxes - Flat Pack?

A: We primarily use high-quality, food-grade virgin fiber paperboard, often with an internal PE or PLA coating for enhanced grease and moisture resistance. This ensures compliance with food safety regulations and provides excellent structural integrity for various food items.

-

Q: Are these boxes environmentally friendly or recyclable?

A: Yes, the base paperboard is recyclable. Options for FSC-certified paperboard (from sustainably managed forests) and bio-based PLA coatings (for industrial composting) are available upon request, allowing businesses to align with their sustainability goals.

-

Q: Can the Printed Large Chip Scoop / Boxes - Flat Pack be customized with our brand's logo and design?

A: Absolutely. Custom printing is one of our core strengths. We offer full customization for graphics, colors, and branding elements using advanced flexographic or offset printing techniques. Our design team can work with your existing branding guidelines or assist in developing new concepts.

-

Q: What is the typical lead time for an order?

A: Lead times vary based on order volume, customization requirements, and current production schedules. For standard custom orders, typical lead times range from 4 to 6 weeks after final artwork approval. Expedited options may be available for urgent requirements.

-

Q: How should the flat-packed boxes be stored to maintain their quality?

A: To maintain optimal quality, it is recommended to store the flat-packed Printed Large Chip Scoop / Boxes - Flat Pack in a cool, dry environment, away from direct sunlight and excessive humidity. Proper storage ensures material integrity and prevents warping or damage before assembly.

Conclusion: The Future of Efficient Food Packaging

The Printed Large Chip Scoop / Boxes - Flat Pack stands as a testament to the evolution of modern food service packaging. It encapsulates the convergence of functionality, brand promotion, and operational efficiency, all within a compact, ready-to-assemble format. As consumer preferences continue to shift towards convenience, hygiene, and environmental responsibility, the demand for intelligently designed, high-performance packaging solutions will only intensify. By investing in these advanced scoop boxes, businesses are not merely acquiring a container111; they are adopting a strategic tool that enhances brand visibility, optimizes operational flow, and reinforces their commitment to quality and sustainability. Our expertise in material science, precision manufacturing, and responsive client partnership positions us as the ideal collaborator for businesses aiming to elevate their packaging strategy and secure a competitive edge in the dynamic food service landscape.

References

- Robertson, G. L. (2016). Food Packaging: Principles and Practice (3rd ed.). CRC Press.

- European Food Safety Authority (EFSA). (2020). Guidance on the use of the EFSA chemical risk assessment toolbox for the safety evaluation of chemicals in food. EFSA Journal, 18(11), e06334.

- United States Food and Drug Administration (FDA). (2023). Food Additives and GRAS Notices. Code of Federal Regulations, Title 21.

- Forest Stewardship Council (FSC). (2022). FSC Standards for Responsible Forest Management.

- British Retail Consortium Global Standards (BRCGS). (2021). Global Standard for Packaging Materials (Issue 6).