Navigating the Landscape of Food Packaging: Focus on Greaseproof Solutions

The dynamic food service industry continually seeks innovative packaging solutions that not only ensure food safety and maintain product quality but also enhance brand visibility and align with growing sustainability mandates. In this highly competitive environment, specialized packaging, such as Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm, emerges as a critical component for businesses aiming to optimize their operational efficiency and elevate customer experience. Current industry trends underscore a significant shift towards materials that offer superior barrier properties against grease and moisture, alongside the ability for bespoke branding. This evolution is driven by consumer demand for hygienic, convenient, and aesthetically pleasing food presentation, coupled with stricter regulatory requirements concerning food contact materials. Furthermore, the global emphasis on reducing plastic waste has spurred a remarkable innovation in paper-based solutions, making products like greaseproof paper an increasingly viable and preferred choice. The market for paper packaging is projected to grow substantially, with greaseproof paper solutions playing a pivotal role due to their inherent biodegradability and recyclability, addressing the dual challenges of performance and environmental responsibility. This focus on specialized packaging is not merely about containment but about preserving food integrity from kitchen to consumer, minimizing waste, and strengthening brand identity through high-quality, custom printing. The integration of advanced printing technologies allows for vibrant, food-safe designs that transform a functional item into a powerful marketing tool, making every meal served an extension of the brand's commitment to quality and detail. Businesses must consider not only the immediate cost but the long-term benefits in terms of customer satisfaction, repeat business, and compliance with evolving environmental standards. The ability of specialized greaseproof paper to maintain the crispness of fried foods while preventing grease stains on external packaging or hands significantly elevates the consumer's perception of quality and care.

The demand for high-performance food packaging is particularly acute in the quick-service restaurant (QSR) sector, takeaway services, and catering businesses, where product freshness and presentation directly impact customer satisfaction. Traditional packaging materials often fall short in managing oily or greasy food items, leading to compromised appearance and potential leakage, which can detract from the dining experience. Modern greaseproof paper, specifically engineered for high-fat content foods like fish and chips, offers a robust solution. This specialized paper typically features a high-density, super-calendared surface and may undergo chemical treatments or mechanical processes to achieve its exceptional grease resistance, often measured by the Kit test or Cobb test standards. Moreover, the integration of custom printing capabilities on such materials provides an unparalleled opportunity for businesses to reinforce their brand messaging, promotions, and contact information directly on the packaging that reaches the consumer's hands. This direct marketing channel is highly effective, as the packaging becomes an integral part of the product experience. The increasing consumer awareness regarding sustainable practices also propels the adoption of paper-based solutions, with certifications like FSC (Forest Stewardship Council) becoming a significant differentiator for brands committed to responsible sourcing. The adaptability of sizes, such as the 230 x 335mm dimensions tailored for 9-inch fish and chips boxes, highlights the industry's move towards precision engineering in packaging to perfectly fit specific product requirements, thereby reducing material waste and optimizing packaging efficiency. This precise sizing ensures that the food is snugly wrapped, maintaining temperature and preventing movement during transit, which is crucial for preserving food quality. The strategic deployment of effective packaging directly influences brand perception and customer loyalty, positioning it as a fundamental element of a comprehensive business strategy rather than a mere operational necessity. The commitment to using high-quality, purpose-built packaging demonstrates a brand’s dedication to excellence across all touchpoints, from product preparation to final consumption.

Technical Specifications and Material Excellence

The efficacy of Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm stems from its meticulously engineered technical parameters and material composition. Typically manufactured from virgin wood pulp, this paper undergoes specialized processes to achieve its non-stick, grease-resistant properties. The grammage, often referred to as GSM (Grams per Square Meter), is a crucial parameter, commonly ranging from 38 GSM to 45 GSM for optimal balance between flexibility and grease resistance. A higher GSM generally indicates greater robustness and a superior barrier. The manufacturing process involves refining cellulose fibers to create a dense, tightly bonded sheet, often through supercalendering, which compresses the paper to reduce porosity and enhance its barrier properties without the need for chemical coatings in some traditional methods. However, modern iterations might incorporate food-grade barriers like fluorochemicals (though declining due to environmental concerns, PFAS-free alternatives are emerging) or silicone derivatives to achieve superior oil holdout. The paper's surface treatment is critical; it must be resistant to oil penetration, typically measured by the Kit Test (TAPPI T 559) or the Turpentine Test (ISO 6586), which assesses the time taken for a specific substance to penetrate the paper. For food contact materials, compliance with international standards such as FDA 21 CFR 176.170 (for paper and paperboard in contact with aqueous and fatty foods) and European Regulation EC 1935/2004 is non-negotiable, ensuring safety and non-toxicity. The specific dimensions of 230mm x 335mm are precisely calibrated to fit standard 9-inch fish and chips boxes, minimizing overhang and ensuring a neat, professional presentation while maximizing material efficiency. This precision cut not only contributes to aesthetic appeal but also reduces material waste during packaging processes, reflecting an environmentally conscious approach. The paper's wet strength is also a vital attribute, preventing disintegration when exposed to moisture from steam or condensation, a common challenge with hot food items. This resilience ensures that the paper maintains its structural integrity throughout the consumer's experience, from serving to consumption.

Printing on greaseproof paper necessitates the use of food-grade, low-migration inks, typically applied via flexographic printing or sometimes offset printing, ensuring that no harmful substances leach into the food. Flexographic printing, known for its high-speed and cost-effectiveness on large runs, allows for intricate and vibrant custom designs, enabling brands to display logos, marketing messages, or even QR codes for digital engagement. The printing quality must adhere to stringent color consistency and image sharpness standards to maintain brand integrity. Moreover, the environmental certifications, such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification), are increasingly important, assuring consumers and businesses that the paper originates from sustainably managed forests. The lifespan of Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm is typically determined by its storage conditions and intended use, but the material itself is designed for single-use applications in food service, providing immediate hygiene and convenience. However, its shelf life, prior to use, is extensive under dry, stable conditions, usually several years. For B2B buyers, understanding these technical details is paramount for assessing product suitability, ensuring regulatory compliance, and making informed procurement decisions that align with both operational demands and corporate social responsibility goals. The investment in high-quality greaseproof paper with precise specifications pays dividends in preventing product spoilage, enhancing customer satisfaction through superior food presentation, and reinforcing a brand's commitment to quality and safety. This level of technical specificity ensures that the packaging performs its intended function flawlessly, maintaining the integrity of the food and the cleanliness of the serving environment, which are critical factors in the fast-paced food service industry.

Key Technical Parameters of Printed Greaseproof Paper

Manufacturing Process: Precision and Quality Assurance

The production of Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm is a sophisticated multi-stage process that prioritizes material integrity, functional performance, and consistent quality. It begins with the selection of high-grade virgin wood pulp, typically sourced from sustainably managed forests, which is then pulped and refined to create a homogeneous slurry. This slurry is then fed into a papermaking machine, where it is laid out onto a fine mesh screen, allowing water to drain and forming a wet web of fibers. This web is then pressed and dried. The key to greaseproof paper lies in the subsequent supercalendering process, where the paper passes through a series of highly polished, heated rollers under intense pressure. This mechanical treatment compacts the fibers, reducing the paper's porosity and creating a dense, smooth surface that inherently resists grease penetration without requiring a separate chemical coating in many cases, although some modern variants may still apply a food-grade barrier layer for enhanced performance or specific properties like PFAS-free coatings. Quality control at this stage involves continuous monitoring of grammage, caliper (thickness), and initial grease resistance using on-line testing methods to ensure consistency. Following the paper production, the large rolls of greaseproof paper proceed to the printing stage. This is predominantly achieved through flexographic printing, a high-speed rotary printing method that uses flexible relief plates and fast-drying, food-grade inks. The design, including logos, branding elements, and safety information, is transferred onto the paper with precision, ensuring crisp lines and vibrant colors that withstand the rigors of food service environments. The choice of ink is paramount; only low-migration, non-toxic inks certified for direct food contact are utilized, adhering to strict food safety regulations like FDA and EU standards. After printing, the large printed rolls are then moved to the slitting and sheeting machines, where they are precisely cut into the final 230mm x 335mm dimensions. This cutting process employs high-precision blades to ensure consistent sizing, crucial for efficient integration into existing packaging lines and for a neat fit within the designated fish and chips boxes. Each batch undergoes rigorous quality assurance checks at various stages. This includes visual inspections for print quality, color accuracy, and material defects, as well as laboratory testing for grease resistance (e.g., Kit Test, Cobb Test), wet strength, and compliance with food contact safety standards (e.g., heavy metal content, migration testing). Furthermore, batch traceability systems are implemented, allowing for full visibility from raw material to finished product. This comprehensive process, from pulp to precise cut and print, ensures that the final Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm meets the highest industry standards for performance, safety, and aesthetic appeal, providing a reliable and visually appealing solution for quick-service restaurants, takeaway outlets, and catering services. The emphasis on robust manufacturing and stringent quality control protocols throughout the entire production lifecycle differentiates premium greaseproof papers from general-purpose alternatives, ensuring that businesses can trust the product to perform consistently under demanding conditions.

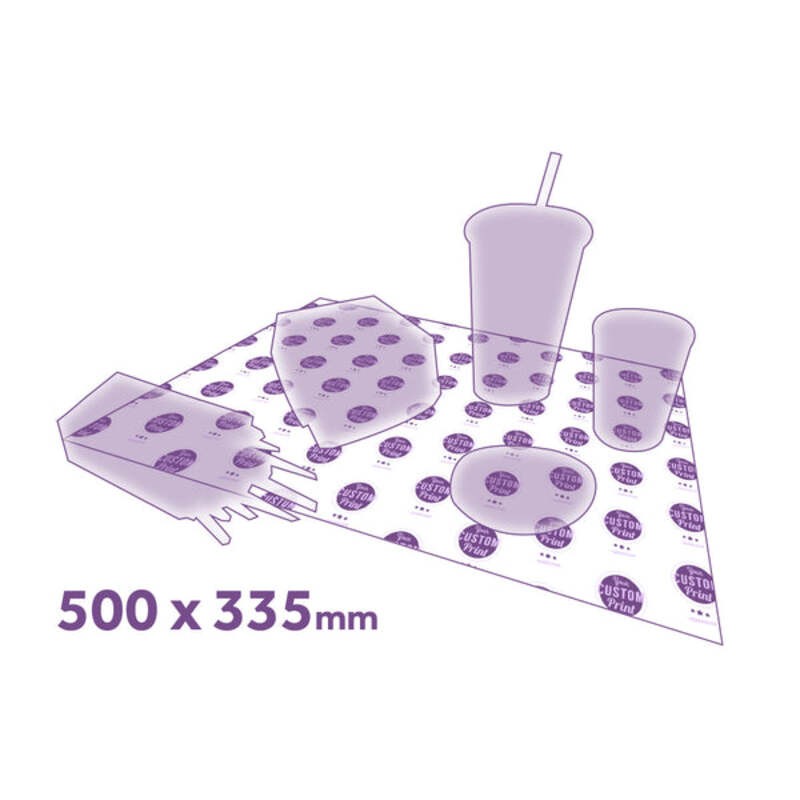

The applicable industries for Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm are predominantly within the food service sector, including but not limited to quick-service restaurants (QSRs), independent fish and chip shops, street food vendors, catering companies, and event concessionaires. Its design specifically targets the challenges associated with serving hot, oily, or fried foods, where preventing grease bleed-through is paramount for maintaining food quality, ensuring hygiene, and protecting external packaging. In these scenarios, the paper acts as an effective barrier, absorbing excess oil and preventing it from soaking through the outer box, which keeps hands clean and the packaging aesthetically appealing. For QSRs, where speed and presentation are critical, this product streamlines the packaging process and enhances the customer's unboxing experience. For independent shops, custom printing offers an affordable yet powerful way to build local brand recognition and loyalty. The lifespan of the product during its functional use is typically short-term, designed for a single meal service, but its impact on product quality and customer satisfaction is significant. Its robust construction ensures that it does not tear or disintegrate under the warmth and moisture of freshly cooked food, thereby maintaining its structural integrity throughout the consumption period. This prevents the common issue of flimsy paper collapsing or becoming saturated, which can lead to messy situations and negative customer perceptions. Beyond its functional benefits, the printed aspect of the greaseproof paper serves as a potent marketing tool. Each sheet becomes a canvas for branding, promotions, or even storytelling, turning a mundane piece of packaging into a memorable touchpoint. This provides an excellent return on investment for businesses seeking to maximize their brand exposure in a cost-effective manner. From a hygiene perspective, its single-use nature minimizes cross-contamination risks, aligning with stringent food safety protocols. The paper's ability to maintain the crispness of fried foods by allowing steam to escape while containing grease is a key advantage, especially in takeaway situations where food quality can degrade rapidly during transit. This balance of moisture management and grease containment is a testament to its specialized engineering, offering a superior alternative to generic food wraps. The focus on specific dimensions, 230 x 335mm, perfectly complements the standard sizing of fish and chips boxes, ensuring an optimal fit that maximizes both functionality and visual appeal, preventing unnecessary material overhang or gaps.

Strategic Advantages and Customization

The strategic advantages of adopting Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm extend beyond mere functionality, encompassing significant benefits for brand building, operational efficiency, and environmental responsibility. From a technical standpoint, its superior grease and moisture barrier properties directly translate into an enhanced consumer experience, preventing leaks, stains, and maintaining the integrity of the food. This directly addresses one of the most common complaints in takeaway food service: messy packaging. By keeping the outer packaging clean and the food optimally presented, businesses foster a perception of quality and attention to detail. The integration of custom printing is a formidable marketing advantage. Unlike plain packaging, printed greaseproof paper transforms every served meal into a branding opportunity. Logos, taglines, special offers, or even social media handles can be prominently displayed, increasing brand recall and encouraging repeat business. This "walking advertisement" effect is invaluable, particularly for businesses operating in highly competitive urban environments where differentiation is key. Customization also allows for seasonal promotions or special event branding, offering flexibility in marketing strategies without requiring significant investment in new packaging molds or designs. Economically, while initial investment in custom printed materials might seem higher than generic alternatives, the long-term benefits in terms of customer satisfaction, increased brand loyalty, and reduced complaints often outweigh the marginal cost difference. Furthermore, the precise 230mm x 335mm dimensions, tailored for 9-inch fish and chips boxes, optimize material usage, reducing waste and potentially lowering per-unit packaging costs in high-volume operations. This bespoke sizing eliminates the need for manual trimming or excessive folding, streamlining the packaging process and saving valuable time during peak hours. In an era where sustainability is a major concern, the paper-based nature of this product, especially when sourced from certified sustainable forests (FSC/PEFC), positions businesses as environmentally conscious. This resonates strongly with a growing segment of consumers who prioritize eco-friendly options, enhancing a brand's reputation and attracting a broader customer base. The ability for this paper to be biodegradable and often compostable (depending on specific coatings and local facilities) further strengthens its environmental profile compared to plastic-lined alternatives. The non-toxic, food-grade inks used ensure compliance with health regulations, protecting both consumers and the brand from potential liabilities associated with unsafe food contact materials. The professional appearance conveyed by custom-printed, high-quality greaseproof paper subtly communicates a commitment to excellence across all facets of the business, from food preparation to presentation.

When considering custom solutions for Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm, businesses should engage with manufacturers who offer comprehensive design and production services. A robust customization process typically involves initial consultation to understand branding guidelines, desired aesthetics, and functional requirements. This is followed by graphic design support, where experienced designers translate concepts into print-ready artwork, considering color profiles, resolution, and ink limitations specific to greaseproof paper. Proofing stages, including digital proofs and sometimes physical samples, are crucial to ensure the final product meets expectations before mass production. Manufacturers often provide guidance on material selection, discussing options for different grammages, levels of grease resistance, and sustainable certifications to match specific operational needs and budgetary constraints. For example, some applications might require a higher GSM for extremely oily foods, while others may prioritize maximum recyclability. The flexibility in order quantities, from small batches for testing or seasonal promotions to large-scale production for national chains, is also a key factor. Established manufacturers typically have advanced flexographic printing capabilities, allowing for high-definition imagery and precise color matching, which is vital for maintaining brand consistency across various packaging materials. They also adhere to strict quality control protocols, including ISO 9001 certification, ensuring that every batch meets the specified technical parameters and safety standards. Furthermore, reputable suppliers will offer comprehensive customer support, assisting with logistics, delivery schedules, and post-purchase inquiries. This end-to-end service ensures a seamless experience from concept to delivery, empowering businesses to leverage their packaging as a strategic asset. The ability to customize not just the print but also subtle elements like paper texture or specific barrier properties (e.g., opting for PFAS-free alternatives) allows businesses to fine-tune their packaging for optimal performance and brand alignment. This bespoke approach ensures that every sheet of greaseproof paper serves multiple functions: it protects the food, reinforces the brand, and communicates a commitment to quality and sustainability. Ultimately, investing in custom Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm is an investment in brand equity, operational efficiency, and a superior customer experience, providing a tangible competitive edge in the fast-paced food service market.

Manufacturer Comparison and Real-World Applications

When selecting a supplier for Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm, businesses should conduct a thorough manufacturer comparison based on several critical criteria beyond just unit cost. Key factors include the manufacturer's adherence to food safety certifications (e.g., BRCGS Packaging Materials Standard, HACCP, FDA compliance for food contact materials), their printing capabilities (e.g., number of colors, print registration accuracy, use of food-grade inks), and their commitment to sustainability (e.g., FSC/PEFC certification, availability of compostable options). Service reliability, including lead times, minimum order quantities (MOQs), and logistical support, is also paramount, especially for businesses with high-volume demands or fluctuating seasonal needs. Reputable manufacturers will typically offer detailed technical datasheets, providing transparent information on GSM, grease resistance values (e.g., Kit Rating), wet strength, and compliance statements. Comparing these technical specifications can help buyers identify products that best meet their specific requirements for food types and serving conditions. For instance, a manufacturer specializing in high-performance coatings might offer superior oil holdout for extremely greasy items, while another might excel in eco-friendly, PFAS-free solutions. Furthermore, assessing a manufacturer's design support capabilities is crucial for businesses seeking highly customized branding; some offer in-house design teams, while others require print-ready artwork. Case studies and customer testimonials can provide valuable insights into a manufacturer's track record, demonstrating their ability to deliver consistent quality and reliable service. For example, a successful partnership with a large QSR chain would indicate robust production capacity and adherence to strict corporate standards. Businesses should also inquire about their quality control processes, such as ISO 9001 certification for quality management systems, which signifies a structured approach to ensuring product consistency. The longevity of a manufacturer in the market and their established client base often correlate with their reliability and expertise in the specialized field of food packaging. Engaging with multiple suppliers to obtain quotes and samples allows for a comprehensive comparison, enabling businesses to make an informed decision that balances quality, cost, and service. This due diligence ensures that the chosen supplier can consistently meet the high standards required for food contact materials and contribute positively to the brand's reputation. A long-standing commitment to research and development, evidenced by new product innovations or improvements in existing materials, also speaks to a manufacturer's dedication to meeting evolving industry demands and regulatory changes.

Real-world applications of Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm showcase its versatility and effectiveness across various food service scenarios. In a bustling fish and chip shop, for instance, these pre-cut and printed sheets significantly speed up packaging times, as staff can quickly line boxes without needing to tear or cut paper from a roll. This efficiency is critical during peak hours, reducing queues and improving customer throughput. The greaseproof barrier ensures that the hot, freshly fried fish and chips do not leave unsightly oil stains on the cardboard box or the customer's hands, maintaining a premium presentation from the point of sale to consumption. The custom branding on the paper reinforces the shop's identity, transforming a simple wrapper into a marketing asset. For large-scale catering operations, where food is prepared off-site and transported, this specialized paper ensures that food quality is preserved during transit. It helps to regulate moisture, preventing the fried items from becoming soggy, while containing grease within the packaging, thus protecting insulation bags and delivery vehicles from contamination. Imagine a corporate lunch delivery where numerous fish and chips boxes are stacked; the greaseproof lining prevents any oil from seeping onto other food items or documents, maintaining a professional image. In street food markets or festival environments, where convenience and quick service are paramount, the ease of use and immediate brand recognition provided by printed greaseproof paper makes it an indispensable tool. It allows vendors to maintain hygiene standards, deliver a consistent product appearance, and reinforce their unique brand among a myriad of competitors. Customer feedback consistently highlights the appreciation for packaging that keeps food fresh and hands clean, directly correlating to repeat business and positive word-of-mouth. The adaptability of this specific size, 230 x 335mm, for the common 9-inch fish and chips box exemplifies a thoughtful design that addresses a precise market need. This product streamlines operations, elevates customer experience, and serves as a powerful, yet subtle, brand ambassador, demonstrating how specialized packaging is an integral part of a successful food service strategy. Its use cases span from local takeaways to major event caterers, all benefiting from its specialized properties for managing hot, greasy foods while simultaneously enhancing brand visibility.

Frequently Asked Questions (FAQs)

- Q: Is the Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm food-safe?

- A: Absolutely. Our printed greaseproof paper is manufactured using virgin wood pulp and printed with food-grade, low-migration inks that comply with stringent international food safety regulations, including FDA 21 CFR 176.170 and European Regulation EC 1935/2004. These certifications ensure that the paper is safe for direct contact with food and will not leach harmful substances, protecting both consumer health and your brand's reputation. We maintain strict quality control protocols throughout the production process to guarantee that every sheet meets these rigorous standards, providing peace of mind for our clients in the food service industry. Our commitment to safety is paramount, as is our dedication to providing transparent documentation of all relevant certifications upon request, allowing businesses to confidently integrate our packaging into their operations while fully adhering to industry best practices and regulatory requirements. This level of compliance is critical for any business handling consumable products, ensuring consumer trust and avoiding potential legal and health complications associated with non-compliant materials. The selection of materials and inks is based on extensive research and adherence to the latest industry guidelines for food contact, making our product a reliable choice for any food business prioritizing safety and quality.

- Q: What is the typical lead time for custom printed orders?

- A: Lead times for custom printed orders of Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm can vary depending on the complexity of the design, order volume, and current production schedules. Generally, after final artwork approval, production and delivery typically range from 4 to 6 weeks. This timeline includes plate making for flexographic printing, manufacturing, quality checks, and logistics. For urgent requirements, we encourage clients to discuss their specific needs with our sales team, as expedited options may be available depending on production capacity. Our goal is to provide realistic and reliable delivery schedules to help you manage your inventory effectively. We pride ourselves on efficient communication and proactive updates throughout the order process, ensuring you are always informed about the status of your custom packaging. Planning ahead and placing orders well in advance, especially for large volumes or during peak seasons, is always recommended to avoid any potential disruptions to your supply chain. We work closely with our logistics partners to ensure timely and secure delivery of your customized greaseproof paper, minimizing any downtime for your operations. Furthermore, our dedicated customer support team is always available to answer any questions regarding order status or delivery details, providing a seamless procurement experience from initial inquiry to final delivery at your premises.

- Q: Is this greaseproof paper environmentally friendly and recyclable?

- A: Yes, our Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm is designed with sustainability in mind. It is made from virgin wood pulp, a renewable resource, and is often sourced from sustainably managed forests with FSC or PEFC certifications where available, ensuring responsible forestry practices. As a paper-based product, it is generally biodegradable. Its recyclability depends on the specific coatings used and the local recycling infrastructure. Most non-coated or minimally coated greaseproof papers are recyclable in paper recycling streams. We are committed to offering eco-friendly options, including PFAS-free and compostable varieties, to align with evolving environmental standards and client preferences. We encourage businesses and consumers to check with their local recycling facilities regarding the acceptance of greaseproof paper. Our continuous efforts in research and development are focused on enhancing the environmental profile of our products without compromising on performance, ensuring that our packaging solutions contribute positively to a circular economy. We provide transparent information on the environmental attributes of our products, helping businesses make informed choices that resonate with their corporate sustainability goals. Our mission is to provide high-quality packaging solutions that not only serve their primary function but also minimize environmental impact, catering to the growing demand for responsible and greener alternatives in the packaging industry. This commitment extends to exploring innovative materials and production methods that further reduce our ecological footprint while maintaining competitive pricing and superior product quality for our diverse clientele.

- Q: What kind of quality assurance and warranty do you offer?

- A: We uphold the highest standards of quality assurance throughout the manufacturing process of our Printed Greaseproof for 9 Inch Fish & Chips Box - 230 x 335mm. Our facilities adhere to ISO 9001 quality management systems, ensuring consistent product quality, from raw material sourcing to final production and packaging. Each batch undergoes rigorous testing for key parameters such as grammage, grease resistance, wet strength, and print quality, alongside comprehensive checks for food safety compliance. We offer a product warranty against manufacturing defects, ensuring that the paper meets the agreed-upon specifications. In the unlikely event of any issues, our dedicated customer support team is readily available to provide assistance, conduct investigations, and facilitate appropriate resolutions swiftly. Our commitment extends beyond the sale, aiming to build long-term partnerships based on trust and mutual success. We believe in the quality and reliability of our products, and our warranty is a testament to this confidence. Furthermore, our transparent batch traceability system allows us to pinpoint the origin and production details of every order, enabling rapid response to any quality concerns. This comprehensive approach to quality and customer service reflects our dedication to exceeding client expectations and ensuring complete satisfaction with every purchase, solidifying our reputation as a trusted supplier in the B2B packaging sector. We provide detailed documentation on our quality control procedures and certifications, reinforcing our commitment to delivering superior products that consistently perform under demanding operational conditions.

Further Resources and References

- Food and Drug Administration (FDA) – Code of Federal Regulations, Title 21, Part 176.170: Components of Paper and Paperboard in Contact with Aqueous and Fatty Foods.

- European Commission Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food.

- TAPPI Technical Information Sheet (TIS) 0306-01: Grease Resistance of Paper and Paperboard (Kit Test).

- International Organization for Standardization (ISO) 6586: Paper, board and pulps — Determination of oil absorptiveness — Turpentine test method.

- Forest Stewardship Council (FSC) Principles and Criteria for Forest Stewardship.

- British Retail Consortium Global Standards (BRCGS) for Packaging Materials.