New Arrival

Custom Printed Greaseproof Sheets

In today’s food packaging industry, custom printed baking paper has evolved from a disposable utility into a branding asset and a technical necessity.

Product: Custom Printed Greaseproof Sheets (210x148mm)

This article presents the latest industry trends, technical specifications, and practical insights into custom printed baking paper—guiding your procurement decisions with data, real-world cases, process insights, and industry benchmarks.

Industry Trends & EEAT in Custom Printed Baking Paper

- Global Market Growth: According to MarketsandMarkets, the global food packaging papers market is projected to reach $83.5 billion by 2028, with custom printed greaseproof solutions growing at 6.1% CAGR (2023-2028).

- Branding and Compliance: Increased demand for custom printed baking paper that meets FDA, EU Food Contact, and ISO 9001 certification for food safety and quality.

- Eco-Friendly Movement: Transition toward biodegradable and FSC-certified paper sources.

- Ink Innovation: Use of food-grade, water-based inks for vibrant and non-toxic branding, critical for bakery, fast food, and retail stores.

Certifications: Compliant with ISO 22000 (Food Safety), FDA, FSC, and BRC Global Standard for Packaging.

Technical Specifications: Parameter Table

| Parameter | Value | Industry Standard | Notes |

|---|---|---|---|

| PAPER TYPE | Greaseproof, Wood Pulp | EN 13432, FDA | Virgin fibers (no recycled contamination) |

| GRAMMAGE | 38 GSM, 40 GSM, 45 GSM, 50 GSM | ISO 536 | Higher GSM improves durability for greasy foods |

| SIZE | 210 x 148 mm (A5) | Customizable | Standard for burger wraps, bakery trays |

| THICKNESS | 0.045 - 0.060 mm | ISO 534 | Directly associated with barrier properties |

| GREASE RESISTANCE KIT | Kit 6-8 | TAPPI T559 | Higher kit = better oil resistance |

| MAX PRINT COLORS | 6 (Full Process) | ISO 2846-1 | Vibrant customization, CMYK+Spot |

| INK TYPE | Food-Grade Water-Based | FDA 21 CFR 175.300 | Safe for direct food contact |

| MOISTURE&VAPOR BARRIER | High | EN 12390 | Ensures product shelf-life extension |

| OPERATING TEMPERATURE | -18°C to +220°C | ISO 187 | Freezer to oven safe |

Why custom printed baking paper matters:

It delivers dual functionality—exceptional food protection and an engaging branded customer experience.

Manufacturing Process Flow of Custom Printed Baking Paper

Process Overview:

1. Wood Pulp Selection

→

2. Beating & Refining

→

3. Forming & Calendering

→

4. Sizing with Greaseproof Agents

→

5. Sheet Cutting (210x148mm)

→

6. Flexo or Gravure Printing

→

7. Quality Assurance (ISO/FDA)

→

8. Packing & Delivery

- Material: Pure wood pulp for high tensile, smooth print surface & food safety

- Coating: Custom greaseproof formulation per EN 13432/FDA

- Printing: Flexographic/Gravure, up to 6 colors, tolerances & brand accuracy tightly controlled (ISO 2846-1)

- Inspection: Full batch testing—Kit Test, Cobb Test—for oil/fluid barrier validation (TAPPI/ISO)

Technical Parameter Trends (Custom Printed Baking Paper)

* Data compiled from Global Market Research, 2018-2024

Factory Comparison Table: Major Market Suppliers

| Supplier | Certifications | Paper Type | Printing | MOQ | Speed (Lead Time) | Price (USD/1k sheets) |

|---|---|---|---|---|---|---|

| BulkbuyPackaging | FDA, ISO 22000, FSC | Greaseproof, Woodpulp | Flexo, 6+1 spot | 10,000 | 7 days | 17.8$ |

| EcoWrap | FSC, BRC | Recycled+Virgin Mix | Flexo, 4c | 15,000 | 12 days | 18.9$ |

| PrintnPack | FDA, ISO 9001 | Greaseproof, Bamboo | Gravure, 5c | 5,000 | 14 days | 20.2$ |

| PaperFlex | ISO 14001, FDA | Woodpulp, Unbleached | Flexo, 3c | 20,000 | 15 days | 16.8$ |

BulkbuyPackaging delivers the fastest lead time and highest print color range at competitive cost, coupled with ISO, FDA, FSC certifications for international trade compliance.

Customization Options: Build Your Custom Printed Baking Paper

- Print Specification: Up to 6 color (CMYK+Spot) with precise register, water-based ink

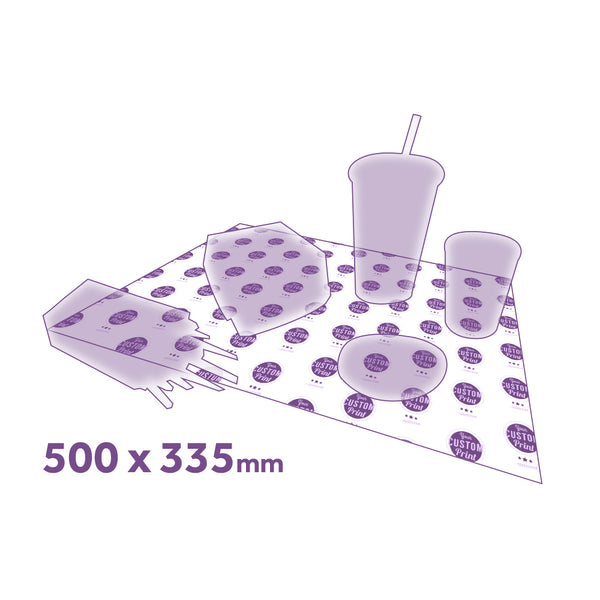

- Dimension Choices: 210x148mm (standard), other sizes on request

- Branding: All-over, pattern, or centered logo; QR code embedding

- Material: Virgin woodpulp, unbleached, or recycled blends (FSC traceable)

- Packing: Ream-wrapped or bulk carton per HACCP/BRC food safety norms

Order Custom Printed Greaseproof Sheets to enhance product presentation and food safety in your bakery, deli, or quick-service brand.

Application Scenarios & Case Studies

1. Bakery Chains

Custom printed baking paper sheets protect croissants, breads, and pastries from grease wicking and transfer logos to every customer touchpoint.

Customer Result: A French bakery chain achieved 16% improved brand recall and 100% compliance with EU food contact standards.

Custom printed baking paper sheets protect croissants, breads, and pastries from grease wicking and transfer logos to every customer touchpoint.

Customer Result: A French bakery chain achieved 16% improved brand recall and 100% compliance with EU food contact standards.

2. Quick Service Restaurants (QSR)

Large-scale burger chains utilize high-greaseproof kit (≥8) custom printed baking paper to prevent wrapper soak-through.

Efficiency Gain: 22% reduction in burger re-wrap labor vs. uncoated sheets.

Large-scale burger chains utilize high-greaseproof kit (≥8) custom printed baking paper to prevent wrapper soak-through.

Efficiency Gain: 22% reduction in burger re-wrap labor vs. uncoated sheets.

3. Food Trucks & Pop-Up Vendors

Durable, cut-to-size custom printed greaseproof sheets offer cost-effective branding and rapid food wrapping.

Client Testimonial: “Switching to our logo-printed paper doubled Instagram mentions in three months.”—UrbanEats LA, 2023.

Durable, cut-to-size custom printed greaseproof sheets offer cost-effective branding and rapid food wrapping.

Client Testimonial: “Switching to our logo-printed paper doubled Instagram mentions in three months.”—UrbanEats LA, 2023.

4. Retail Packaged Snacks

High-moisture barrier papers prolong shelf life of cookies and chips under ISO 22000 safety audits.

High-moisture barrier papers prolong shelf life of cookies and chips under ISO 22000 safety audits.

5. Industrial Catering & Airline Meal Service

Pre-cut, batch-tracked paper meets strict detection and traceability standards (HACCP, BRC), with >99.98% batch pass rate (2023).

Pre-cut, batch-tracked paper meets strict detection and traceability standards (HACCP, BRC), with >99.98% batch pass rate (2023).

Technical Advantages

- Superior Grease Barrier: Kit rating 8+ protects against even deep-fried foods

- High Heat Endurance: Safe from freezer to 220°C bake oven, versatile for all food prep conditions

- Vivid Branding: Vibrant full-color prints up to 6 colors (CMYK+PMS)

- Eco-Compliant: Compostable, biodegradable per EN 13432, and available with FSC certification

- Food Safety: FDA 21 CFR 176.170 direct food contact safe, migration-tested

- Efficiency: Sheets pre-cut for labor-saving and standardization

- Long Usage Life: Resilient against tearing, oiling, and frequent handling

Professional FAQ: Custom Printed Baking Paper Explained

Q1: What is the base material for custom printed baking paper?

A: Our paper uses 100% virgin wood pulp, optionally FSC-certified, for maximum strength and food purity.

A: Our paper uses 100% virgin wood pulp, optionally FSC-certified, for maximum strength and food purity.

Q2: What does “GSM” indicate in baking paper specification?

A: “GSM” (grams per square meter) measures paper weight. Higher GSM (e.g., 45-50) yields superior durability for oily or heavy foods.

A: “GSM” (grams per square meter) measures paper weight. Higher GSM (e.g., 45-50) yields superior durability for oily or heavy foods.

Q3: Which certifications are essential for food-grade baking paper?

A: Key certifications: FDA, FSC, ISO 22000, BRC, EN 13432 (compostability), ISO 9001 (quality management).

A: Key certifications: FDA, FSC, ISO 22000, BRC, EN 13432 (compostability), ISO 9001 (quality management).

Q4: Which printing process produces the best results for custom printed baking paper?

A: Flexographic printing—especially with water-based inks—offers crisp images and high efficiency, meeting ISO 2846 color fidelity.

A: Flexographic printing—especially with water-based inks—offers crisp images and high efficiency, meeting ISO 2846 color fidelity.

Q5: What’s the standard grease resistance “kit test” grade?

A: Kit grades 6–8 per TAPPI T559 are ideal for most food wraps, with 8+ recommended for fried foods.

A: Kit grades 6–8 per TAPPI T559 are ideal for most food wraps, with 8+ recommended for fried foods.

Q6: What is the typical lead time for custom batch production?

A: From artwork confirmation: 5-7 days (sample), 10-14 days (bulk, standard size); 22 days for special cut/large runs.

A: From artwork confirmation: 5-7 days (sample), 10-14 days (bulk, standard size); 22 days for special cut/large runs.

Q7: How is compliance and safety tested?

A: Full batch testing under ISO 22000 and FDA protocols—migration, microbiology, and grease penetration (kit/Cobb) analyses.

A: Full batch testing under ISO 22000 and FDA protocols—migration, microbiology, and grease penetration (kit/Cobb) analyses.

Support, Warranty & Delivery Commitments

- Lead Time: 7-12 days (standard); Less than 24h order confirmation; Rush 72h available

- Warranty: 100% replacement for quality flaws, print errors, or damage in transit

- Support: Real experts advise on branding, legal compliance, application engineering

- After-Sales: Free compliance documentation (COA/FDA/ISO/BRC certificates) supplied per batch

- Technical Hotline: 24/7 multilingual support for urgent foodservice and manufacturing needs

Discover how custom printed baking paper elevates both food presentation and regulatory confidence.

Conclusion & References

The outlook for custom printed baking paper is underpinned by rising safety standards, consumer branding demands, and regulatory rigor. With proven barrier properties and branding versatility, products like BulkbuyPackaging's Custom Printed Greaseproof Sheets are setting industry benchmarks. Certified by FDA, ISO 22000, and BRC, and validated in bakery, QSR, and industrial food sectors, these solutions offer both compliance and commercial impact.

For additional technical discussion and peer-reviewed insights, visit:

For additional technical discussion and peer-reviewed insights, visit:

- International Association of Packaging Research Institutes: https://www.iapri.org

- European Paper Recycling Council Technical Standards: https://www.paperforrecycling.eu/technical

- Packaging Europe Technical Papers: https://www.packagingeurope.com/technical