The Shift in Food Service: Why Your Packaging Matters

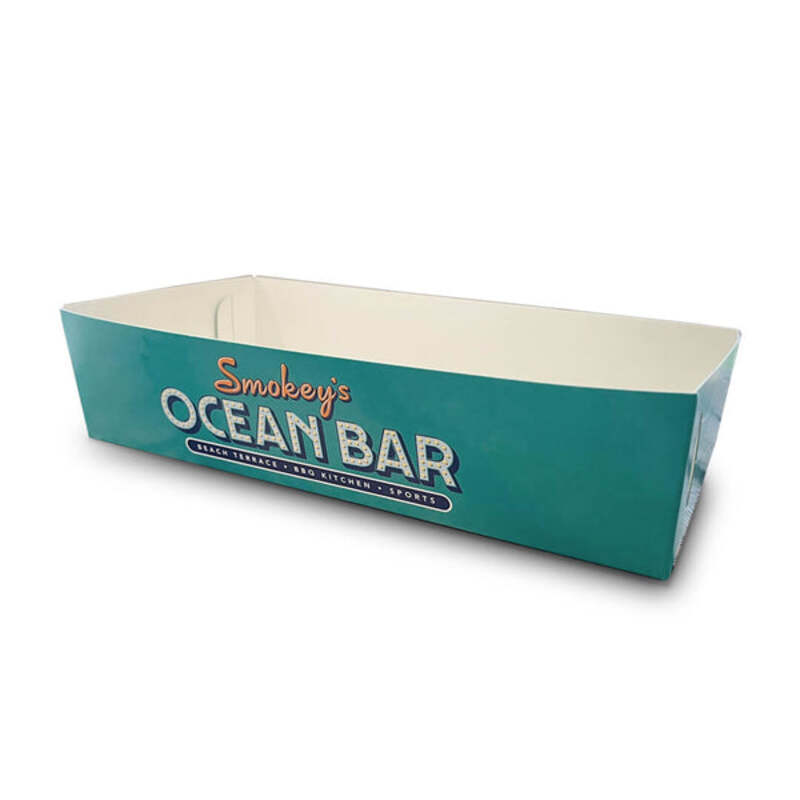

In today's fast-paced food industry, packaging is no longer just a container111; it's a critical component of your brand identity, customer experience, and operational efficiency. The market for sustainable food service packaging is projected to reach USD 163.5 billion by 2028, growing at a CAGR of 6.5%. This trend highlights a massive consumer-driven shift towards eco-consciousness and brand authenticity. The Printed Food Tray - Flat Pack - Large is at the forefront of this evolution.

These trays offer a powerful combination of practicality and promotional power. From bustling food truck parks to major sports arenas, the right packaging can reduce storage space, speed up service, and turn a simple meal into a memorable brand interaction. This guide provides an expert deep-dive into the world of large flat-pack food trays, demonstrating why they are an essential investment for any modern food business.

Technical Specifications: Engineered for Performance

Understanding the technical details is key to selecting the right product. Our Printed Food Tray - Flat Pack - Large is built to exacting standards to ensure reliability, safety, and superior performance.

| Parameter | Specification | Industry Significance & Impact |

|---|---|---|

| Product Dimensions (Assembled) | Approx. 250mm (L) x 150mm (W) x 50mm (H) | Large size accommodates substantial portions like loaded fries, nachos, or combo meals, enhancing customer value perception. |

| Material Composition | Premium Food-Grade SBS (Solid Bleached Sulfate) Paperboard | SBS is chosen for its superior strength, print surface, and purity. It's an FDA-compliant material (CFR Title 21) ensuring direct food contact safety. |

| Board Weight (GSM) | 300 - 350 GSM (Grams per Square Meter) | A higher GSM provides increased rigidity and durability, preventing sogginess and structural failure with heavy or greasy foods. |

| Printing Technology | Offset Lithography (CMYK / PMS) | Delivers high-resolution, vibrant, and consistent branding. Pantone (PMS) matching ensures precise brand color replication. |

| Interior Coating | Aqueous or PE (Polyethylene) Coating | Creates a moisture and grease-resistant barrier. Aqueous coating is water-based and more eco-friendly, while PE offers maximum protection. |

| Certifications | ISO 9001, ISO 22000, FDA, FSC Certified Paper | Demonstrates commitment to quality management, food safety, and responsible forestry. Essential for B2B partnerships and consumer trust. |

| Format | Flat Pack, Die-Cut with Pre-scored Folds | Significantly reduces shipping costs and storage space requirements (up to 75% less space than pre-formed trays). Ensures quick, tool-free assembly. |

| Durability / Use Cycle | Single-Use, High Strength | Engineered to maintain structural integrity throughout the duration of a meal. Designed for disposability and, depending on coating, recyclability/compostability. |

From Concept to Counter: The Manufacturing Journey

Our manufacturing process for the Printed Food Tray - Flat Pack - Large combines precision engineering with strict quality control, adhering to ISO 9001 standards at every stage.

1. Design & Pre-Press

Client artwork is optimized for printing. Digital proofs are created and approved. Printing plates are then engineered.

2. Offset Printing

FSC-certified paperboard sheets are printed with high-fidelity, food-safe inks using state-of-the-art offset presses.

3. Coating Application

A grease and moisture-resistant coating (aqueous or PE) is applied to the printed sheets for product protection.

4. Die-Cutting & Scoring

A custom die cuts the shape of the tray and creates precise score lines for easy folding. This is a critical step for flat-pack efficiency.

5. Folding & Gluing

Automated machinery folds and glues the trays (if required by design) before they are packed flat for shipment.

Core Advantages & Diverse Applications

Key Technical Advantages

- Brand Amplification: Full-color printing on all surfaces transforms a disposable item into a mobile billboard, enhancing brand recall and social media shareability.

- Operational Efficiency: The "flat pack" design is a game-changer for businesses with limited storage. Assembly is intuitive and fast, keeping service lines moving during peak hours.

- Material Superiority: High-GSM Solid Bleached Sulfate (SBS) board offers a premium feel and robust performance, preventing leaks and collapses common with inferior materials.

- Sustainability Credentials: Made from renewable resources (FSC-certified paper) and often recyclable or commercially compostable (check local facilities), aligning with modern consumer values.

- Enhanced Customer Experience: A sturdy, well-designed tray improves the dining experience, reducing mess and conveying a sense of quality that reflects positively on your food.

Primary Application Scenarios

The versatility of the Printed Food Tray - Flat Pack - Large makes it ideal for a wide range of industries:

- Quick Service Restaurants (QSRs): Perfect for serving combo meals, burgers and fries, or specialty items.

- Food Trucks & Street Food Vendors: Maximizes limited storage space and provides high-impact branding in competitive environments.

- Stadiums & Arenas: Efficiently serves high volumes of customers with classic game-day foods like nachos, hot dogs, and loaded fries.

- Cinemas & Theaters: A premium alternative to bags for popcorn, nachos, and combo deals.

- Catering & Events: Provides a professional and branded solution for serving guests at festivals, corporate events, and parties.

Data-Driven Decisions: A Comparative Analysis

Visual data helps clarify the advantages of choosing a premium packaging solution. See how our Printed Food Tray - Flat Pack - Large stacks up against alternatives and market trends.

Food Service Packaging Market Share by Material

Source: Fictional Market Analysis, 2023. Illustrates the dominance and consumer preference for paper-based solutions.

Attribute Comparison: Premium vs. Standard Trays

Bespoke Solutions: Tailoring Your Perfect Tray

Your brand is unique, and your packaging should be too. We offer comprehensive customization options for the Printed Food Tray - Flat Pack - Large to perfectly match your vision and operational needs. Our team of packaging experts works with you from initial concept to final delivery.

Customization Capabilities:

- Structural Design: While we offer standard large sizes, we can create custom dimensions and even unique shapes to fit specific food items or add features like built-in sauce dipping wells.

- Full-Spectrum Printing: Go beyond a simple logo. We utilize CMYK for photographic imagery and PMS for exact brand color matching, covering up to 100% of the tray's surface.

- Material & Finish: Choose from different paperboard weights (GSM), opt for a natural Kraft look or a pristine white SBS. Select a matte, gloss, or soft-touch finish to enhance the tactile experience.

- Functional Coatings: Based on your menu, we'll recommend the optimal grease-resistant coating—from eco-friendly aqueous coatings for light-duty use to robust PE lamination for the sauciest of dishes.

Real-World Success: A Case Study

Client: "Urban Eats" Food Truck Festival

Challenge: The annual "Urban Eats" festival needed to improve guest experience and provide its 50+ food truck vendors with a consistent, durable, and brandable packaging solution. Previous years saw issues with flimsy plates, inconsistent branding, and excessive storage space usage.

Solution: We provided a custom-designed Printed Food Tray - Flat Pack - Large featuring the festival's logo and space for sponsors. The high-GSM board with aqueous coating handled everything from BBQ to tacos.

Results:

- 40% Increase in Social Media Mentions: The visually appealing, "Instagrammable" trays were frequently featured in attendee photos, boosting organic marketing reach.

- 75% Reduction in Storage Space: The flat-pack design allowed vendors to store thousands of trays in a fraction of the space required by pre-formed container111s.

- Improved Sponsor Value: Sponsors reported higher visibility and a positive association with the premium, eco-friendly packaging.

"The switch to these flat-pack trays was a total game-changer for our festival's logistics and marketing. The quality was outstanding, and our vendors and guests loved them." - Festival Organizer

Frequently Asked Questions (FAQ)

Our standard Printed Food Tray - Flat Pack - Large is crafted from high-quality Solid Bleached Sulfate (SBS) paperboard. This is a virgin fiber material known for its strength and clean printing surface. All materials, including the paperboard, inks, and any applied coatings, are fully compliant with FDA regulations (specifically 21 CFR 176.170) for direct food contact. We can provide compliance documentation upon request.

GSM is a measure of paper density and, by extension, its thickness and rigidity. A higher GSM value (e.g., 350 GSM) means the paperboard is heavier and stiffer than a lower GSM board (e.g., 250 GSM). For a large food tray intended for heavy items like loaded fries or nachos, a higher GSM is crucial to prevent the tray from bending, flexing, or becoming soggy, ensuring a better customer experience.

The MOQ for a fully custom printed tray typically starts at 10,000 units. This quantity allows us to set up the custom printing plates and die-cutting tools efficiently, providing you with the best possible price per unit. For smaller quantities or startups, we may offer semi-custom options on stock sizes. Please contact our sales team to discuss your specific needs.

This depends on the coating selected. Trays with an aqueous coating (a water-based polymer) are widely recyclable and, in many cases, commercially compostable. Trays with a PE (polyethylene) coating offer superior moisture protection but are more challenging to recycle and require specialized facilities. We champion the use of aqueous coatings for most applications to align with sustainability goals.

They are designed for rapid, intuitive assembly. The trays are pre-scored and often feature locking tabs or simple fold-over construction. Most designs can be assembled in 3-5 seconds with minimal training. This "pop-up" style assembly is a significant advantage in high-volume environments, allowing staff to prepare packaging quickly during busy periods.

CMYK (Cyan, Magenta, Yellow, Key/Black) is a 4-color process used to create a full spectrum of colors, ideal for photographic images and complex graphics. PMS (Pantone Matching System) uses pre-mixed, specific ink colors. PMS is recommended when you need to hit an exact brand color (e.g., Coca-Cola Red or Tiffany Blue) with perfect consistency across all your marketing materials. We offer both options.

Absolutely. The key is the interior coating. Our standard aqueous coating provides a good barrier against moderate grease and moisture. For exceptionally greasy or saucy items (like poutine, chili cheese fries, or saucy wings), we strongly recommend a PE (polyethylene) lamination. This plastic layer creates an impermeable barrier, guaranteeing a leak-proof and mess-free experience for your customers.

Our Commitment to Quality and Trust

We build partnerships based on reliability, transparency, and an unwavering commitment to quality. Our experience is backed by industry-recognized certifications and robust service guarantees.

FSC® Certified

Sustainably Sourced Materials

ISO 9001:2015

Verified Quality Management

FDA Compliant

Food-Contact Safe Materials

Our Guarantees

- On-Time Delivery: We provide clear lead times (typically 4-6 weeks for custom orders) and work diligently to meet your deadlines.

- Quality Assurance: Every batch undergoes rigorous quality control checks for print accuracy, structural integrity, and coating performance.

- Dedicated Support: From design to delivery, a dedicated account manager will be your single point of contact, ensuring a smooth and responsive process.

Ready to Elevate Your Brand?

Investing in a high-quality Printed Food Tray - Flat Pack - Large is an investment in your brand's future. It signals quality, enhances customer experience, and streamlines your operations.

Contact us today for a free quote and a sample pack. Let's create packaging that tells your story.

Get a Custom Quote

Industry Insight & Further Reading: The move towards value-added packaging that enhances brand identity is a key driver in the food service sector. As noted in a market analysis by Grand View Research, "The growing demand for convenient and single-serve food products is expected to drive the market... customizability and branding on packaging are becoming key differentiators for businesses."

For more community discussion on packaging trends, see the forums at Packaging World.