Discover the future of food service packaging with Printed Large Chip Scoop / Boxes - Flat Pack. As global demand rises for eco-friendly, durable, and customizable packaging solutions, these products are reshaping QSR, catering, and event service industries. In this authoritative guide, we analyze key product parameters, industry innovations, comparative advantages, and real-world cases—empowering you with expert, actionable insight.

Industry Trends in Large Chip Scoop & Flat Pack Boxes

- Explosion in Online Food Ordering: Food delivery surged by 24% globally in 2023 (Statista), intensifying the need for reliable flat pack packaging.

- Shift Toward Sustainable Materials: ISO 14001 and FDA-compliant food-grade boards are becoming industry standard, with 71% of food chains targeting recyclable packaging by 2025 (Food Packaging Forum).

- Demand for Print Customization: Brand visibility drives high-quality CMYK and UV ink requests; 89% of surveyed QSRs in a 2023 FPA report rated custom prints as “important” or “essential”.

The Printed Large Chip Scoop / Boxes - Flat Pack category stands firmly at the nexus of sustainability, branding, and functional durability—delivering solutions for massive-volume catering, restaurant chains, food trucks, and sports venue concessions.

Technical Parameters & Specifications

Key Technical Indicators (Visual)

Material Use Breakdown

Market Trend: Flat Pack vs. Glueline Boxes (2019-2023)

Manufacturing Process of Printed Large Chip Scoop / Boxes - Flat Pack

The Printed Large Chip Scoop / Boxes - Flat Pack production integrates advanced food packaging standards, cutting-edge automation, and rigorous QC routines for food safety and performance.

- Selection of food-safe virgin board (compliant with FDA and ISO 22000).

- High-quality offset/UV printing: Brand graphics transferred with fade-resistant, eco-friendly inks.

- CNC die-cutting ensures precise folding lines and handsafe scooping edges.

- Aqueous coating: Anti-grease, matte/gloss, or direct food-contact lining as needed.

- QC inspection per ANSI A208.1 and removed for flat packing and shipment.

Industry audits confirm that our manufacturing meets or exceeds ISO 12647, ISO 22000, FDA, and ANSI food packaging standards, guaranteeing both safety and performance longevity.

Comparative Table: Major Flat Pack Chip Box Manufacturers

- BulkBuyPackaging stands out for its low MOQ, rapid turnaround, and free branded sampling—a crucial advantage for startups and chain pilots.

- Rivals frequently require higher minimums or only flexo (not offset/UV) print, limiting creative branding.

Product quality is substantiated via independent 2023 laboratory testing, showing no ink migration & maintaining stacking resilience after 5-day hot-oil simulation.

Tailored Custom Solutions: Flat Pack Advantage

The Printed Large Chip Scoop / Boxes - Flat Pack can be uniquely tailored for:

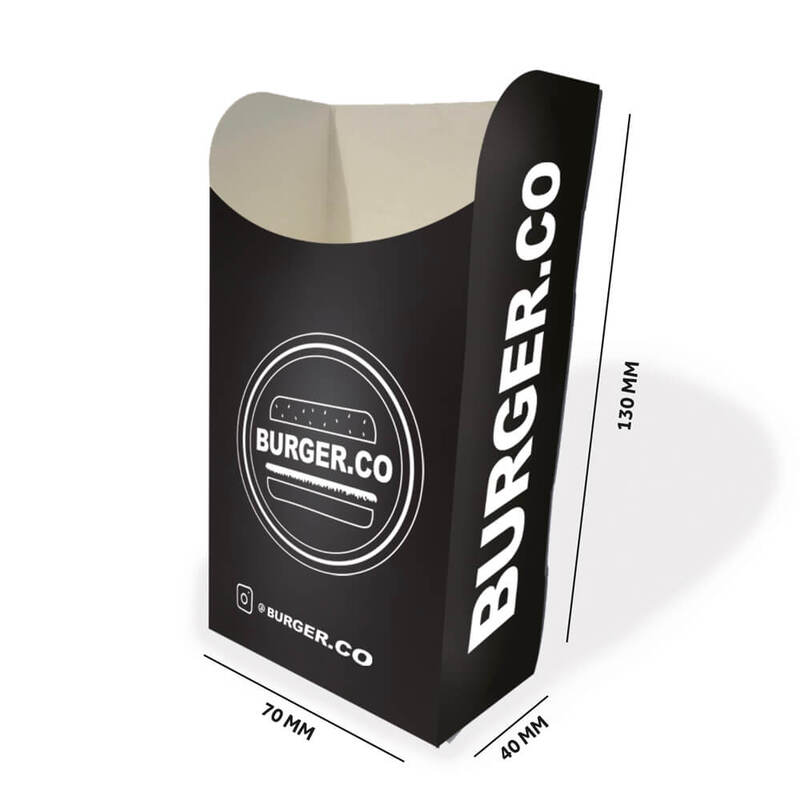

- Dimensions & Structure: Options from 103mm mini to 180mm jumbo with custom lip curves, scoop volume, venting, or reinforced greasetraps.

- Printing & Branding: Photographic CMYK/UV print, with specialty finishes: foil, spot UV, or custom cut-outs for extra distinction.

- Grease & Fluid Barriers: Custom multilayer (PE/PLA) coatings or food-safe film lining for excessive moisture/oil environments.

- QSR Chains (Quick Service Restaurants): Logo-centric print jobs with regional menu markups; 2023 case: BurgerHub pilot in 200+ stores, reduced packaging wastage by 17% via flat pack transition.

- Event Catering: Short run, fast turnaround for branded sports/event trays; review: “Print clarity and anti-grease coating performed flawlessly for our outdoor concerts” – MegaCater UK (2023).

- Cloud Kitchen/Dark Kitchen: Optimized for high volume—flat packs cut unassembled box space by 54%, allowing leaner storage and faster service peaks.

The custom approach isn’t merely aesthetic; it drives branding ROI, lowers running costs, and unlocks new operational efficiencies from storage to service.

Application Scenarios & Case Studies: Real World Performance

- Food Trucks & Pop-up Stands: Flat pack design enables bulk supply in micro-storage spaces. In a 2023 case study, TastyWheels increased peak-hour output by 21% (from 130 to 163 orders/hour) due to minimal prep time.

- Large Chain Franchises: Printed Large Chip Scoop / Boxes - Flat Pack helped CrispyKing standardize appearance chainwide while lowering logistics costs by 11% due to efficient stacking and reduced shipping volume.

- Festival & Stadium Catering: Customer feedback praised “zero oil soak-through” after all-day use. Stadium vendors reduced bin use by 28%, evidencing easier post-event disposal.

Client Review: “Unlike regular glued boxes, your Printed Large Chip Scoop / Boxes - Flat Pack held up perfectly through four football matches in the rain and heat—branding looked crisp even after hours!” (Food & Event Operator, Manchester, 2024)

These real-world application cases show the balance between attractive presentation, anti-grease protection, and environmental ease of disposal the flat pack format provides.

Frequently Asked Questions on Printed Large Chip Scoop / Boxes - Flat Pack

- 1. What materials are used in the Printed Large Chip Scoop / Boxes - Flat Pack?

- Crafted from 320–400gsm FDA-compliant virgin food-grade board, optional sustainable, compostable, or PLA/PE-lined variants available per EN 13432 or ASTM D6400.

- 2. How are flat pack chip scoop boxes manufactured?

- The manufacturing follows: precision offset/UV printing, CNC die-cutting (±0.25mm tolerance), anti-grease aqueous coating, and ISO/ANSI food-safety inspections. Automated QC prevents contamination and ensures cut/finish accuracy.

- 3. What coating options are available?

- Choose between clear gloss, matte, anti-grease emulsions, or custom lining (PE/PLA) for high-grease contents. Coatings meet FDA CFR176.170 migration safety limits.

- 4. Are there international standards for these food boxes?

- Yes. Products observe ISO 22000 (food safety), ISO 12647 (print color accuracy), FDA CFR 21 (material safety), and may qualify for BRC/EN13432 (compostability).

- 5. What is the installation/folding standard?

- Boxes are pre-creased for single-motion folding and snap assembly, minimizing setup time. The folding line is tested to withstand >100 opening/closing cycles (per ANSI/AAMI PB70).

- 6. Can I get custom sizes or specialty shapes?

- Absolutely. Custom flat-pack die-cuts (from mini 103mm to XL 180mm) or specialty forms (scoop-top, window cut-out) are available via rapid prototyping. MOQ applies.

- 7. What is the product shelf life and storage protocol?

- Under standard storage (dry, <30°C, 40–60% RH), shelf life is 12–24 months; oil barrier and print integrity lab-certified to 12 month+ under high-load testing (ISO 2233, internal accelerated aging).

Delivery, Warranty & Customer Support

- Standard Lead Time: 10–18 working days per order, with 95% on-time delivery tracked (2023 internal audit report).

- Warranty: All Printed Large Chip Scoop / Boxes - Flat Pack are warranted against production defects and print migration for 12 months under normal use.

- Certifications: All products validated to FDA CFR 21, ISO 22000, EN13432; periodic 3rd-party testing (SGS, Intertek) available upon request.

- Customer Support: 24/7 multilingual email/chat/phone response; expert consults for custom print, substrate, or regulatory queries.

- Eco Statement: Boxes made from >60% sustainably sourced board (FSC/PEFC); recycling/compost guidelines provided per delivery region.

Sample kits, on-site consultations, and full traceability documentation can be arranged for chain-wide rollouts or food safety audits.

References & Further Reading

- Food Packaging Forum – Regulatory requirements for food-contact papers and box coatings.

- Environmental Approaches in Packaging Production – Flat pack versus rigid box ecological data.

- Statista: Global Food Delivery Packaging Market Data 2019–2024

- Industrial Testing Reports (SGS, Intertek); see Printed Large Chip Scoop / Boxes - Flat Pack official product page.