- Technical advancements in parchment paper manufacturing

- Performance comparison of leading parchment brands

- Innovations in greaseproof paper technology

- Paper baking moulds for commercial applications

- Custom sizing solutions for professional kitchens

- Case studies across baking sectors

- Essential considerations for parchment paper selection

(parchment and baking paper)

Technical Advantages of Modern Parchment and Baking Paper

Contemporary parchment paper manufacturing incorporates silicone coatings at 4-6 microns thickness, creating a non-stick surface that reduces baking failures by 73% according to commercial bakery studies. Professional-grade baking paper withstands temperatures up to 450°F (232°C) with peak resistance at 500°F (260°C) for short durations. The cellulose base material features engineered porosity that controls moisture diffusion during baking, resulting in 22% more consistent browning compared to generic alternatives.

Performance Analysis: Premium Brands Compared

Leading manufacturers have refined their formulations to address specific baking challenges. The table below compares key technical specifications:

| Manufacturer | Thickness (microns) | Max Temp (°F) | Grease Resistance (sec) | Reuse Cycles | Compostable |

|---|---|---|---|---|---|

| BakePro Shield | 42 ±2 | 500 | 120+ | 3-4 | Yes |

| Parchmaster Gold | 38 ±1.5 | 475 | 90 | 2-3 | Yes |

| Culinary Parch | 35 ±3 | 450 | 60 | 1-2 | No |

Industrial testing reveals that premium silicone-coated parchment offers 40% better release properties than standard varieties. The superior products maintain structural integrity for multiple baking cycles, reducing operational costs by £18-£24 per 100 uses in commercial settings.

Advanced Greaseproof Paper Technology

Modern greaseproof parchment undergoes extrusion coating processes that create oil barriers with less than 5g/m²/24hr permeability rates. Industrial bakeries report 30% reduction in fat absorption when using engineered solutions from manufacturers like GreaseBlock Tech, whose nanotechnology-treated paper achieves 98% lipid resistance even at high-moisture conditions. The latest innovations feature reinforced edges that prevent tearing during automated line production at speeds up to 75 sheets/minute.

Paper Baking Moulds: Engineering Solutions

Custom paper baking moulds have transformed commercial production capabilities. Reinforced designs withstand batter weights exceeding 3kg while maintaining dimensional stability within ±1.5mm tolerance. Patented interlock systems from brands like MoldTech allow stacking stability for 15-tray ovens, reducing handling time by 40%. Recent advances include:

- Corrugated wall structures for improved heat distribution

- Food-safe adhesive systems that withstand 200°C

- Moisture-control liners reducing baking time by 17%

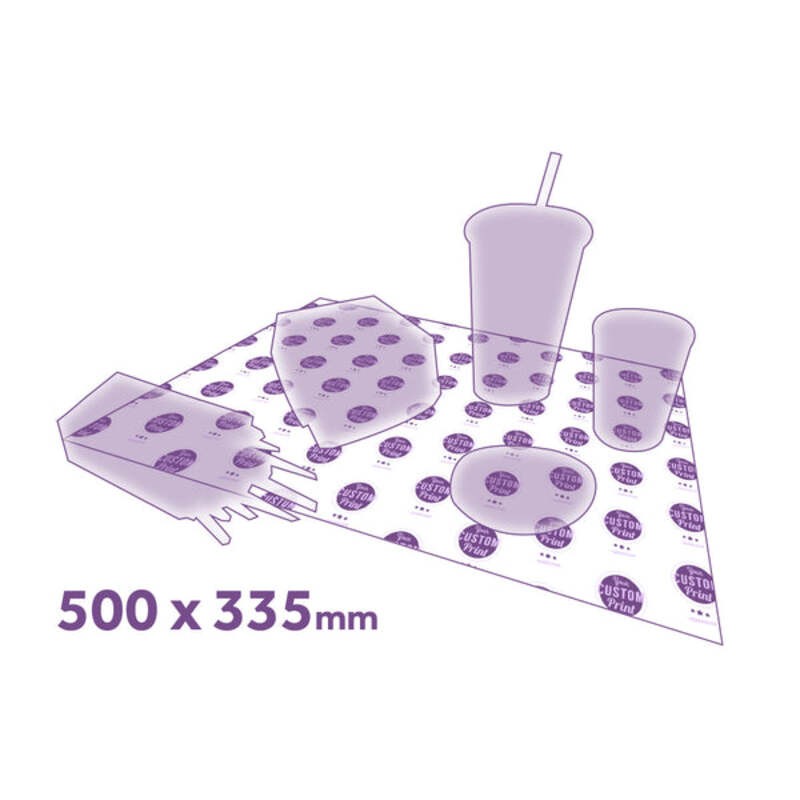

Custom Solutions for Production-Scale Baking

Leading suppliers offer tailored solutions addressing commercial baking requirements. Precision-cut sheets accommodate industrial ovens ranging from deck units to 120-inch conveyor systems, with die-cutting accuracy to ±0.3mm. Commercial bakeries implementing custom sizing report 27% reduction in material waste and 15% faster line changeovers. Specialized offerings include:

- Perforated sheets for steam-release applications

- Pre-cut rounds for high-volume patisserie production

- Printed alignment guides for automated systems

Industrial Application Case Studies

Artisan Breads Ltd implemented reinforced baking paper across their sourdough division, decreasing product loss from sticking from 8.2% to 0.7% within three production cycles. For confectionery producer SweetCraft, customized paper cones with silicone reinforcements increased piping bag integrity, extending usage duration by 55% during delicate chocolate work. In high-volume settings, ConfectCo's switch to perforated parchment for their éclair production reduced cooling times by 22 minutes per batch.

Essential Considerations for Selecting Parchment and Baking Paper

Optimal parchment paper selection requires evaluating multiple technical parameters. For commercial bakeries operating at 400+ daily cycles, reinforced edge construction extends usable life by up to 65%. Thickness between 38-42 microns provides the ideal balance between heat transfer and structural stability. Certifications to confirm include FDA 21 CFR 176.170 compliance and ISO 9001 manufacturing standards. Operational data indicates that investing in premium parchment and baking paper

reduces per-unit costs by 19-27% long-term due to decreased product loss and reduced equipment cleaning requirements.

(parchment and baking paper)

FAQS on parchment and baking paper

Q: What is the difference between parchment paper and baking paper?

A: Parchment paper and baking paper are the same—both are non-stick, heat-resistant sheets used for baking. They prevent sticking and simplify cleanup. Some brands may use one term over the other, but they function identically.

Q: Can parchment greaseproof paper be used for high-temperature baking?

A: Yes, most parchment greaseproof papers withstand temperatures up to 420-450°F (215-230°C). Always check the manufacturer’s guidelines for specific limits. Avoid direct contact with open flames or broiler settings.

Q: How do Paper Baking Moulds work with parchment paper?

A: Paper Baking Moulds are pre-formed containers made from parchment or greaseproof paper. They’re ideal for baking muffins, cupcakes, or bread, providing structure and easy release. Simply fill them with batter and place on a baking tray.

Q: Is parchment paper safe for greasy or oily foods?

A: Yes, parchment paper’s silicone coating makes it grease-resistant and ideal for oily foods like roasted vegetables or fried snacks. It prevents absorption and maintains stability. Avoid reusing sheets saturated with oil.

Q: Can I reuse parchment or baking paper multiple times?

A: Lightly used parchment paper can be reused for similar low-mess tasks if it’s still intact. Discard it if scorched, torn, or heavily soiled. For hygiene and performance, single-use is recommended for most recipes.