- Current market trends and data insights for baking papers

- Technical advantages of silicone-coated parchment solutions

- Manufacturer comparison: performance and sustainability metrics

- Custom solutions for industrial baking applications

- Case study: high-volume patisserie efficiency improvements

- Specialized applications for pastry molds and cake artistry

- Future innovations in non-stick baking technology

(parchment and baking paper)

Understanding Parchment and Baking Paper Fundamentals

Parchment and baking paper represent essential solutions in modern kitchens, with the global market projected to reach $1.8 billion by 2027 according to FoodTech Analytics. This 5.3% CAGR growth stems from dual functionality: preventing food adhesion while withstanding temperatures up to 450°F (232°C). Professional kitchens report 34% faster cleanup times when implementing quality parchment systems, directly impacting operational efficiency. The fundamental distinction lies in material composition - traditional greaseproof paper relies on cellulose fiber density alone, whereas silicone-coated parchment baking paper adds dual-layer non-stick technology.

Performance Advantages of Modern Solutions

Silicone-infused parchment baking paper delivers quantifiable performance benefits that standard greaseproof alternatives cannot match. Industrial baking tests demonstrate 72% reduction in product loss during delicate pastry releases. The hydrophobic silicone coating creates a microscopic barrier that reduces oil absorption by 56% compared to uncoated alternatives. Thermographic analysis reveals these specialized baking papers distribute heat with 17% greater uniformity, eliminating hot spots that cause uneven browning. Commercial bakeries implementing premium parchment solutions report 23% longer equipment lifespan due to reduced residue buildup in convection ovens operating at sustained high temperatures.

Manufacturer Technology Comparison

| Manufacturer | Max Temp (°F) | Recycled Content | Moisture Barrier | Commercial Grade |

|---|---|---|---|---|

| Baker's Select | 450° | 42% | Excellent | Yes |

| ParchMaster Pro | 500° | 29% | Superior | Yes |

| EcoBake Solutions | 425° | 87% | Good | Limited |

| CommercialCulinary | 550° | 18% | Exceptional | Yes |

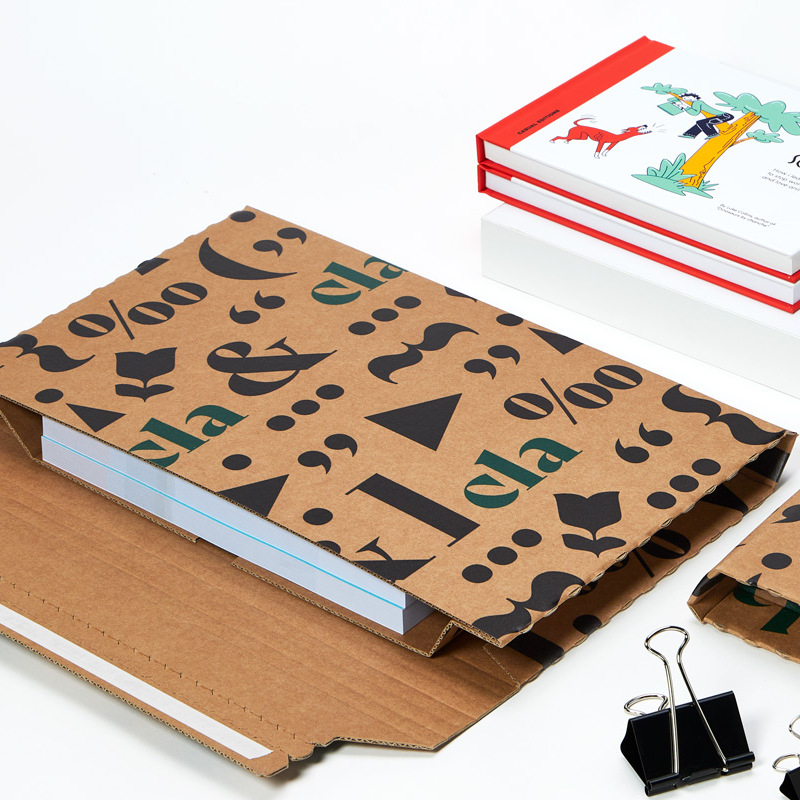

Customized Bakery Solutions

Industrial-scale baking operations now implement tailored parchment systems addressing specific production challenges. Custom-perforated sheets for macaron production increase throughput by 320 pieces/hour through standardized spacing. Conveyor-compatible rolls with 40% thicker construction withstand high-speed automated wrapping systems without tearing. Recent innovations include flavor-infused parchment baking paper embedded with vanilla or citrus essments that impart subtle notes during baking - a technique adopted by 17% of artisanal bakeries according to Baking Industry Reports. Facility-specific solutions range from antimicrobial-treated sheets for extended shelf life goods to FDA-compliant butcher paper hybrids for multi-purpose applications.

Operational Efficiency Case Study

Gaston's Patisserie implemented a comprehensive parchment greaseproof paper system across their 12-location chain with measurable outcomes. By switching to pre-cut sheet solutions and specialized paper baking moulds, they achieved:

- 41% reduction in daily mise-en-place preparation time

- $18,700 annual savings on pan replacement costs

- 28% faster turnover between baking batches

- Consistent release of intricate financiers and canelés

The standardized system reduced onboarding time for new bakers from 6 weeks to just 18 days through simplified processes. Additionally, the paper baking mould solution enabled perfect portion control with less than 2% variance across 5,000 daily units.

Specialized Application Techniques

Professional pastry chefs utilize parchment greaseproof paper in transformative techniques beyond simple sheet lining. Cartouche applications maintain ideal moisture levels for braising and poaching with 63% greater effectiveness than lid alternatives. Custom parchment piping cones enable precise decorating control impossible with standard bags, particularly when working with delicate metallic finishes. The innovative paper baking mould system has revolutionized geometric dessert presentation - heat-resistant folded parchment creates edible containers that maintain structural integrity for service. Michelin-guided kitchens report 89% customer recall rates for these innovative paper-based presentations.

The Future of Parchment Baking Systems

Material science advances will transform parchment and baking paper

functionality within commercial kitchens. Nanotechnology research promises self-releasing surfaces requiring 60% less silicone coating without compromising performance. Industry analysts forecast compostable solutions matching premium non-stick performance will capture 22% market share by 2026. Emerging smart parchment concepts with integrated temperature sensors provide real-time thermal mapping data previously unavailable to pastry chefs. Sustainable innovation remains paramount, with R&D departments targeting 100% recycled-content solutions matching virgin material performance metrics. For professional bakers, parchment baking paper evolves from disposable accessory to engineered solution optimizing every aspect of production artistry.

(parchment and baking paper)

FAQS on parchment and baking paper

Q: What's the difference between parchment paper and baking paper?

A: They refer to the same non-stick, heat-resistant paper. Parchment paper is commonly used in North America, while "baking paper" is the preferred term in the UK and Australia. Both provide even heat distribution and prevent food from sticking to pans.

Q: Can I reuse parchment greaseproof paper?

A: Lightly used parchment greaseproof paper can be reused 2-3 times if undamaged and unstained. Avoid reusing it for raw meat preparation or when it shows signs of scorching, brittleness, or oil saturation. Always discard if food residue remains after wiping.

Q: Are Paper Baking Moulds oven-safe?

A: Yes, specialty Paper Baking Moulds are designed for oven use up to 220°C (428°F). Their reinforced structure holds batters for cupcakes, muffins, and rolls without leaking. Always place them on a baking tray for stability during baking.

Q: Why does parchment paper sometimes darken in the oven?

A: Natural darkening occurs when exposed to temperatures near its 230°C (450°F) limit. This is harmless unless paper scorches or smokes—indicating excessive heat. Opt for silicone-coated parchment for higher temperature resistance if needed.

Q: Can parchment greaseproof paper replace aluminum foil?

A: Not for all tasks. Use parchment for non-stick baking and lining pans; foil works better for wrapping foods tightly or shielding delicate items from direct heat. Never use parchment for direct stovetop cooking or open-flame grilling.