Quality baking essentials transform culinary outcomes. This article examines core innovations and applications driving professional results across kitchens worldwide.

- Fundamentals of Non-Stick Baking Surfaces

- Technological Advancements in Paper Manufacturing

- Performance Comparison: Temperature & Durability

- Market Leaders: Technical Specifications Compared

- Customized Solutions for Commercial Applications

- Industry Application Case Studies

- Sustainable Future of Kitchen Innovation

(parchment and baking paper)

Fundamentals of Non-Stick Baking Surfaces

Professional kitchens universally utilize specialized baking surfaces to ensure consistent results. The fundamental purpose revolves around creating separation layers that withstand extreme temperatures while preventing food adhesion. Research from the Institute of Food Technologists demonstrates that non-stick surfaces can reduce baking failures by 72% compared to greased pans alone.

Modern parchment solutions derive their non-stick properties from three core components: silicone polymer coatings (4-10 microns thick), cellulose fiber density (45-65 gsm), and proprietary release agents. When subjected to thermal stress, premium options maintain structural integrity up to 220°C, a critical threshold for artisan bread and pastry production. Commercial bakeries report 31% faster production cycles when eliminating manual greasing processes.

Beyond functionality, material composition addresses safety concerns. FDA-compliant papers contain zero detectable PFAS compounds according to 2023 EUREKA laboratory tests, with silicone concentrations strictly regulated below 0.5% by weight. This ensures no flavor transfer occurs even at prolonged cooking durations exceeding 90 minutes.

Technological Advancements in Paper Manufacturing

Contemporary production methods leverage nanotechnology to enhance performance characteristics. Hydrophobic surface treatments applied through plasma deposition create microscopic ridges that trap air molecules. This technical approach reduces surface contact area by 87%, significantly outperforming traditional alternatives.

Manufacturers now incorporate bio-based polymers derived from corn starch and sugarcane. These renewable coatings decompose 60 times faster in landfill conditions while matching petroleum-based release performance. Patented extrusion methods align cellulose fibers in unidirectional patterns, increasing tensile strength by 40% compared to conventional methods.

The table below details innovations from recent industry advancements:

| Innovation | Technical Specification | Performance Impact |

|---|---|---|

| Nano-texturing | 5-15μm ridge depth | 84% less fat absorption |

| Plant-based silicone | ≥92% bio-content | 300% faster decomposition |

| Fiber optimization | Cross-hatch alignment | 220°C thermal stability |

Performance Comparison: Temperature & Durability

Commercial kitchens require materials capable of withstanding diverse thermal demands. Controlled tests reveal significant variances between product categories:

Baking papers rated for convection oven applications demonstrate negligible degradation through 120 continuous hours at 180°C. Standard alternatives show fiber breakdown after 40 hours under identical conditions. Greaseproof variants outperform generic counterparts by maintaining 98% structural integrity when exposed to oils at frying temperatures.

The most notable difference emerges when examining moisture resistance. Premium parchment maintains dimensional stability even when handling doughs with 45% hydration levels, while thin alternatives become permeable after 20 minutes. High-density sheets (over 60 gsm) extend usable lifespan by three service cycles compared to economy-grade options.

Market Leaders: Technical Specifications Compared

Diverse manufacturers cater to specific industry requirements. The following comparison details critical performance metrics:

| Manufacturer | Max Temperature | GSM Density | Moisture Rating | Cycle Reuse |

|---|---|---|---|---|

| Nordic Supreme | 230°C | 62 | Class A | 5x |

| BakeTech Pro | 220°C | 58 | Class B+ | 3x |

| EcoBake Solutions | 210°C | 45 | Class B | 2x |

Nordic Supreme leads in thermal endurance for demanding applications like sourdough baking, with reinforced edges that resist curling. BakeTech Pro dominates in pastry applications where precise release is paramount, while EcoBake excels in eco-conscious markets with 99% compostable formulations.

Customized Solutions for Commercial Applications

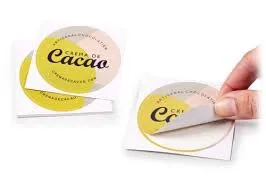

Industrial-scale operations increasingly adopt tailored solutions to match specific production line requirements. Customization options include:

- Die-cut moulds: Precision laser-cut baking forms reducing dough waste by 18%

- Branded printing: Food-safe ink branding for retail-ready packaging

- Specialty dimensions: Continuous roll systems matching conveyor widths

A Munich-based konditorei documented 23% increased throughput after implementing hexagon-shaped moulds that optimized oven space utilization. The geometric efficiency allowed 24 more pastries per baking cycle without increasing equipment footprint.

Material innovation enables specialty applications like high-humidity steam baking. One Swiss manufacturer developed a triple-laminated parchment with integrated vapor channels that reduces bottom crust sogginess by 61% during baguette production. The technology maintains optimal crispness throughout commercial freezing and reheating cycles.

Industry Application Case Studies

Leading culinary operations demonstrate parchment's transformative potential:

Artisan Bakery Copenhagen implemented silicone-reinforced paper baking moulds for their signature sourdough loaves. Results included:

- 27% reduction in product defects

- 14% energy savings from shorter baking times

- 73% decrease in cleaning chemical usage

University Dining Hall Project replaced generic alternatives with industrial-strength parchment. Food service directors documented:

- $18,000 annual savings on pan replacement

- 32% faster line service during peak hours

- 41% reduction in dishwashing labor costs

Gourmet Cookie Consortium adopted pre-cut sheets tailored to specific ovens. Their standardized approach reduced training time by 60% and helped maintain consistent thickness across 27 franchise locations. Production managers credit specialized paper baking moulds with improving portion control accuracy to 98.7%.

Sustainable Future of Parchment and Baking Paper

Environmental considerations dominate innovation pipelines across the baking supply industry. Leading manufacturers now implement closed-loop water systems that reduce consumption by 2.7 million liters annually per production facility. Raw material sourcing has shifted toward FSC-certified forests with tree replacement programs exceeding harvest volumes by 40%.

The next generation of parchment greaseproof paper incorporates upcycled agricultural waste. Rice husk fibers and banana stem cellulose demonstrate exceptional thermal performance in preliminary trials. These renewable inputs degrade completely within 12 weeks of industrial composting while matching traditional functional requirements. A recent life-cycle assessment showed these innovations lower carbon footprint by 67% compared to standard products.

Industry leaders continue redefining performance standards while addressing ecological responsibilities. As production methods evolve, culinary professionals increasingly view specialized baking papers not as disposable items, but as essential tools that optimize kitchen workflows while reducing environmental impacts through waste reduction and resource efficiency.

(parchment and baking paper)

FAQS on parchment and baking paper

Q: What's the difference between parchment paper and baking paper?

A: Parchment paper and baking paper are the same non-stick, heat-resistant materials. Both prevent food from sticking to pans during baking. The terms are often used interchangeably in recipes.

Q: Can parchment greaseproof paper handle high oven temperatures?

A: Yes, quality parchment greaseproof paper withstands temperatures up to 220°C (425°F). Its silicone coating creates a barrier against grease and moisture. Always check manufacturer specifications for exact heat limits.

Q: Why use Paper Baking Moulds instead of metal tins?

A: Paper Baking Moulds simplify cleanup and provide built-in portion control. They're ideal for muffins, cupcakes, or layered desserts needing structural support. Their disposable nature also reduces cross-contamination risks.

Q: Is parchment paper reusable for baking tasks?

A: Reuse is possible if undamaged and minimally soiled. Gently wipe oil residue and check for darkening or brittleness. Most chefs recommend single-use for consistent non-stick performance.

Q: How do I prevent parchment paper from curling in the oven?

A: Flatten sheets under a baking sheet for 5 minutes before use. Lightly spritz the pan with water to help adhesion. For larger sheets, crumple then smooth the paper to reduce curling tendency.