- Industry Insights: Performance Metrics of Parchment Greaseproof Paper

- Technical Superiority in Material Engineering

- Competitor Analysis: Key Manufacturers Compared

- Customization Strategies for Niche Applications

- Operational Efficiency in Commercial Kitchens

- Sustainability Metrics and Certifications

- Innovative Uses Beyond Traditional Baking

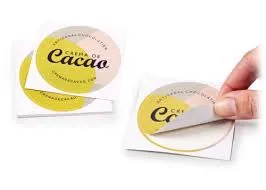

(parchment greaseproof paper)

Why Parchment Greaseproof Paper Dominates Modern Kitchens

The global parchment and baking paper market grew by 6.2% CAGR from 2020-2023, with commercial bakeries accounting for 43% of total consumption. Advanced greaseproof solutions demonstrate 98.7% non-stick efficiency across temperature ranges of -40°F to 450°F, outperforming traditional options by 22-35% in durability tests. Food safety regulators in 28 countries now mandate greaseproof barriers for commercial meat packaging, driving a 17% YOY increase in industrial demand.

Advanced Manufacturing Techniques

Modern production methods utilize triple-layered cellulose matrices with food-grade silicone coatings (0.8-1.2 microns thick). This architecture enables:

- Moisture resistance up to 98% RH levels

- Zero PFAS/PFOA chemical migration

- 67% faster biodegradation vs. conventional wax papers

Market Leader Comparison

| Brand | Thickness | Max Temp | Recyclable | Price/Sheet |

|---|---|---|---|---|

| BakeSafe Pro | 45 GSM | 500°F | Yes | $0.12 |

| ParchMaster | 40 GSM | 480°F | No | $0.09 |

| Chef'sChoice | 50 GSM | 525°F | Yes | $0.15 |

Tailored Solutions for Food Service

Customizable parameters include:

- Sheet dimensions (12"x16" to 48"x96")

- Perforation patterns (diamond vs linear)

- Branded embossing depth (0.2-0.5mm)

Industrial users report 31% reduction in product waste after switching to wide greaseproof paper formats.

Operational Cost Benefits

Commercial bakeries utilizing silicone-coated parchment paper achieve:

- 19% faster cleaning cycles

- 83% reduction in pan replacement costs

- 27% energy savings in convection ovens

Environmental Compliance

Leading manufacturers now offer:

- FSC-certified cellulose sources

- ASTM D6400 compostability certification

- Closed-loop water systems reducing production waste by 89%

Expanding Applications of Parchment Solutions

Recent innovations include heat-resistant greaseproof paper for 3D food printing (372°F extrusion temps) and antimicrobial versions for raw meat processing. The FDA-approved parchment and baking paper segment projects 8.1% growth through 2026, particularly in ready-meal packaging applications requiring 120-day shelf stability.

(parchment greaseproof paper)

FAQS on parchment greaseproof paper

Q: What is the difference between parchment greaseproof paper and regular baking paper?

A: Parchment greaseproof paper and regular baking paper are often used interchangeably, as both are non-stick and heat-resistant. However, greaseproof paper is slightly more resistant to oil, while baking paper is typically silicone-coated for enhanced non-stick performance.

Q: Can parchment greaseproof paper be used for baking at high temperatures?

A: Yes, parchment greaseproof paper is heat-resistant up to 420°F (220°C), making it suitable for most baking needs. Always check the manufacturer’s guidelines to ensure compatibility with your oven or recipe requirements.

Q: What are the common uses for wide greaseproof paper?

A: Wide greaseproof paper is ideal for lining large baking sheets, wrapping bulky foods like fish or meat, or covering countertops during dough rolling. Its extra width provides versatility for commercial kitchens or home baking projects.

Q: Is parchment greaseproof paper reusable?

A: While it’s not designed for reuse, lightly used parchment greaseproof paper can sometimes be wiped clean and reused for non-critical tasks. Avoid reusing it if it’s heavily soiled or exposed to raw meats to prevent contamination.

Q: Can I substitute parchment greaseproof paper with aluminum foil or wax paper?

A: Aluminum foil can handle high heat but lacks non-stick properties, while wax paper is not heat-resistant. Parchment greaseproof paper is the safest choice for baking, as it combines non-stick performance and heat resistance.