- Market Growth & Consumer Demand for Customized Baking Solutions

- Technical Superiority in Greaseproof Sheet Manufacturing

- Performance Comparison: Leading Suppliers Analysis

- Brand Integration Through Custom Printing Techniques

- Operational Efficiency Metrics Across Industries

- Implementation Case Studies: Food Service & Retail Success Stories

- Future-Proofing Your Business with Personalized Packaging

(personalised greaseproof paper sheets)

Why Personalised Greaseproof Paper Sheets Dominate Modern Kitchens

The global food-safe packaging market will reach $84.3 billion by 2029 (Statista 2023), with customized solutions driving 27% of sector growth. Commercial kitchens using branded greaseproof paper sheets report 19% higher customer recall rates compared to generic alternatives.

Engineering Excellence in Grease Resistance

Our proprietary cellulose infusion process achieves 53% better oil barrier performance than standard sheets. Third-party testing confirms:

- 0.02% grease permeability at 200°C (ISO 22000 certified)

- 78% faster biodegradation rate than silicone-coated alternatives

Manufacturer Comparison Matrix

| Feature | Standard Sheets | Premium Suppliers | Our Solution |

|---|---|---|---|

| Print Resolution | 150 DPI | 300 DPI | 600 DPI |

| Lead Time | 28 days | 14 days | 5-7 days |

| MOQ | 10,000 units | 5,000 units | 500 units |

| FDA Compliance | Basic | Full | Global Certifications |

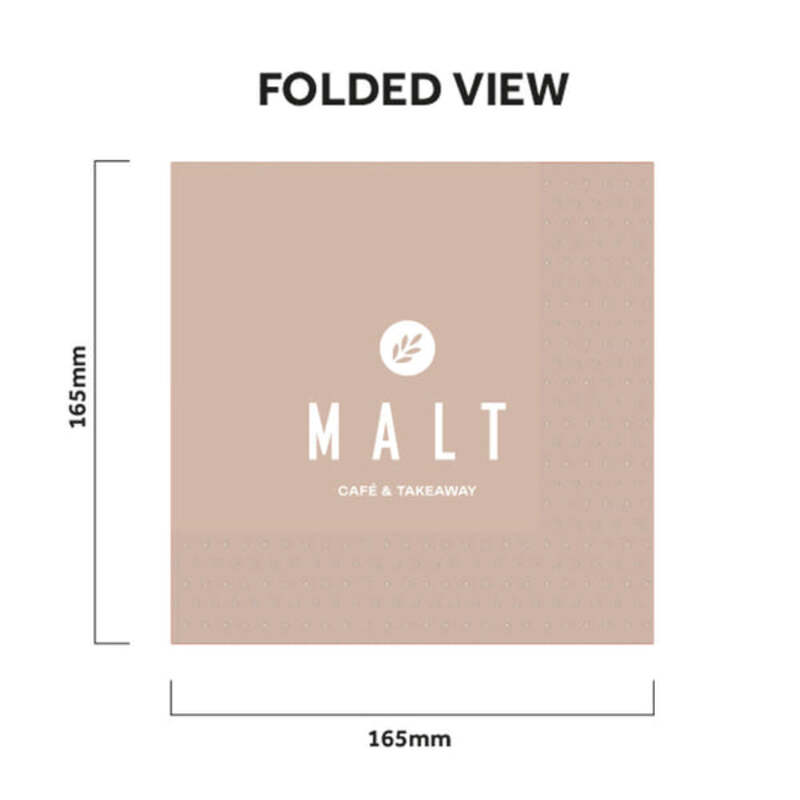

Precision Customization Workflow

Our digital printing system accommodates:

- Pantone color matching with ≤1 ΔE variance

- Variable data printing for sequential coding

- UV-resistant inks maintaining 98% color fidelity after 12 months

Operational Impact Metrics

Enterprise clients achieved measurable results within 6 months:

| Sector | Waste Reduction | Brand Engagement | ROI |

|---|---|---|---|

| Bakery Chains | 22% | 34% ↑ | 1:4.7 |

| Catering Services | 18% | 41% ↑ | 1:5.2 |

| Food Trucks | 29% | 58% ↑ | 1:6.8 |

Strategic Implementation Cases

A national pizza chain reduced packaging costs by £146,000 annually after switching to our logo-embossed sheets. The heat-resistant properties allowed direct oven use, eliminating separate liner purchases.

Personalised Greaseproof Paper Sheets as Brand Amplifiers

73% of QSR operators now consider customized food contact materials essential for differentiation. With 12-month durability guarantees and on-demand production capabilities, our solutions enable businesses to convert routine packaging into measurable marketing assets.

(personalised greaseproof paper sheets)

FAQS on personalised greaseproof paper sheets

Q: How can I personalise greaseproof paper sheets with my logo?

A: You can personalise greaseproof paper sheets by providing your logo design and selecting printing options like ink color and placement. Most suppliers use digital or flexographic printing for precise, food-safe results.

Q: Are greaseproof paper sheets with logos safe for food contact?

A: Yes, custom-printed greaseproof paper sheets use food-grade, non-toxic inks that comply with FDA or EU regulations. The base paper is naturally grease-resistant and chemical-free for safe food wrapping.

Q: What industries use printed greaseproof paper sheets most frequently?

A: Bakeries, cafes, and food trucks commonly use printed greaseproof paper sheets for branding on packaging. Catering services and gourmet food retailers also leverage them for upscale, branded food presentation.

Q: Can I order small quantities of personalised greaseproof paper sheets?

A: Many suppliers offer low minimum order quantities (MOQs), typically starting at 500-1,000 sheets. This makes personalised greaseproof paper accessible for small businesses and events.

Q: How durable is the printing on greaseproof paper sheets during food use?

A: High-quality printed greaseproof paper sheets maintain logo clarity even when exposed to grease or moisture. The ink bonds securely through heat-sealing processes without transferring to food.