The use of paper for pizza has become a global standard in the food industry, driven by increasing delivery volumes, stringent food safety regulations, and growing environmental awareness. Greaseproof sheets and specialty food papers are now manufactured with advanced coatings and printing technology to deliver excellent oil and moisture barrier properties, support branding, and comply with evolving sustainability standards.

- Market Growth: According to the Pizza Marketplace, the worldwide pizza packaging paper market is projected to expand at a CAGR of 5.6% from 2023–2028, led by the North American and Asia-Pacific regions.

- Technology Shift: Introduction of recyclable, compostable, and custom-printed paper for pizza solutions to meet regulatory and consumer expectations (Packaging Digest).

- Consumer Demand: Over 70% of consumers now prefer food packaging that is biodegradable and food-safe (source: Journal of Food & Packaging Science).

- Pizza Box Liners: Barrier layer against grease/oils for takeaway/delivery.

- In-Store Bakery Use: Display, serve and wrap pizza slices for in-house sales.

- Food Service & QSRs: Custom printed sheets for brand promotion and hygiene.

- Frozen Pizza Packaging: Separation and non-stick, especially for parbaked/frozen crusts.

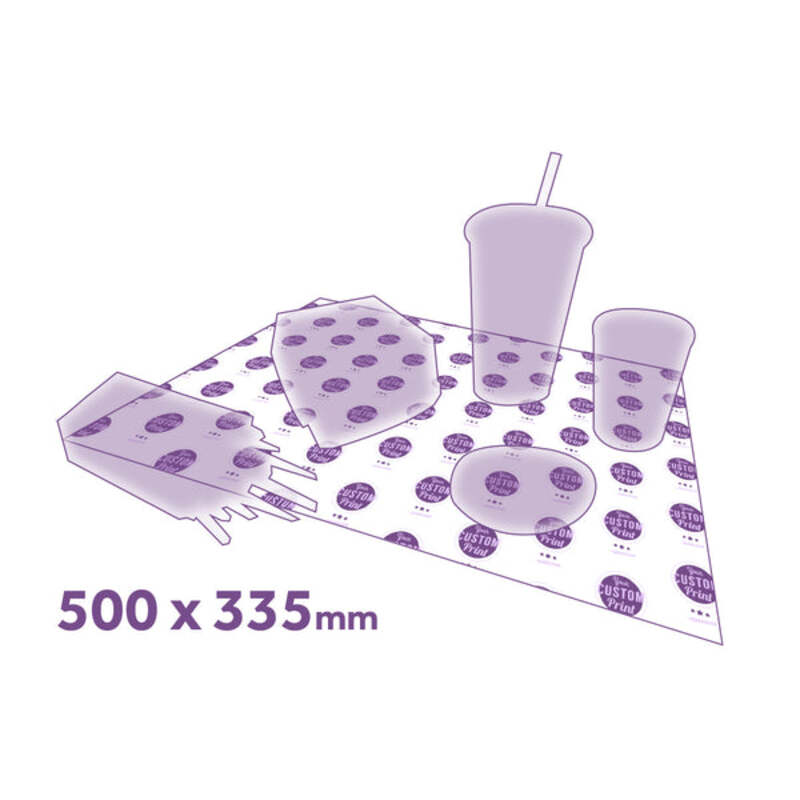

The adoption of high-quality paper for pizza like greaseproof sheets supports food safety, product presentation, and eco-initiatives. BULKBUY PACKAGING offers fully customizable solutions with precise sizing, custom logos, and industry-leading greaseproof performance.

| Parameter | Typical Values | Industry Standard Range | Application Impact |

|---|---|---|---|

| Basis Weight (gsm) | 35–45 gsm | 28–50 gsm | Thickness/Strength |

| Grease Resistance (KIT level) | 6–9 | 5–12 | Oil Barrier |

| Water Resistance (Cobb, g/m²) | <18 | 10–25 | Moisture Protection |

| Heat Resistance (°C) | <220°C | 150–250°C | For Baking/Heating |

| Printing Color Compatibility | Full color (CMYK+PMS) | 1–6 colors | Brand Customization |

| Sustainability | FSC, Compostable | FSC, PEFC, ISO14001 | Environmental Compliance |

| Certification | FDA, EU, LFGB | FDA, BRC, SGS, ISO22000 | Food Contact |

BULKBUY PACKAGING stands at the forefront of paper for pizza technology, offering precision-manufactured greaseproof sheets, personalized printing, and unwavering commitment to food safety. We blend innovation with eco-conscious design, helping food service brands meet evolving regulatory and consumer demands with confidence. Our paper for pizza solutions empower your business with:

- Cutting-edge Oil/Grease Resistance – Ensures pizza quality, hygiene, and optimal delivery experience.

- Eye-catching Printing – Elevates brand identity with food-safe, vivid colors and crisp logos.

- Certified Sustainability – Compostable, recyclable, and FSC verified for a circular economy.

- Technical Service & Customization – Custom sizing, print, and technical support tailored to your needs.

- Fast Turnaround & Worldwide Delivery – Reliable global supply, backed by extensive logistics expertise.

Choose paper for pizza from BULKBUY PACKAGING to safeguard your food, fortify your brand, and embrace a sustainable packaging future.

- Leading Pizza Chain, Europe: Switched to 7 inch printed greaseproof liners, reporting 43% drop in box grease stains and improved customer satisfaction.

- Global QSR Franchise: Used custom logo sheets for cross-market consistency and saw 22% boost in takeout brand recall.

- Organic/Artisan Pizza Shops: Adopted FSC-certified compostable liners aligning with their green ethos and local waste management legislation.

The transformation of food packaging pivots on innovation, reliability, and eco-responsibility. BULKBUY PACKAGING’s paper for pizza stands as the optimal choice for pizzerias, QSRs, and food brands worldwide. With high-performance barrier properties, food-safe certifications, and green credentials, our Pizza Box Printed Greaseproof Sheets. 7 Inch support both operational efficiency and a sustainable future.

- Pizza Marketplace: Greaseproof Packaging Market Trends, 2023

- Packaging Digest: Evolution of Paper Pizza Packaging

- Journal of Food & Packaging Science: Oil and Moisture Resistance in Food Contact Papers

- Food Packaging Forum: Greaseproof Paper in Food Contact

- Food Navigator: Biodegradable Greaseproof Paper Market

Official site: https://www.bulkbuypackaging.com