- Introduction: A Deep Dive into Printed Greaseproof Paper Sheets

- The Rise and Innovation of Greaseproof Paper Solutions

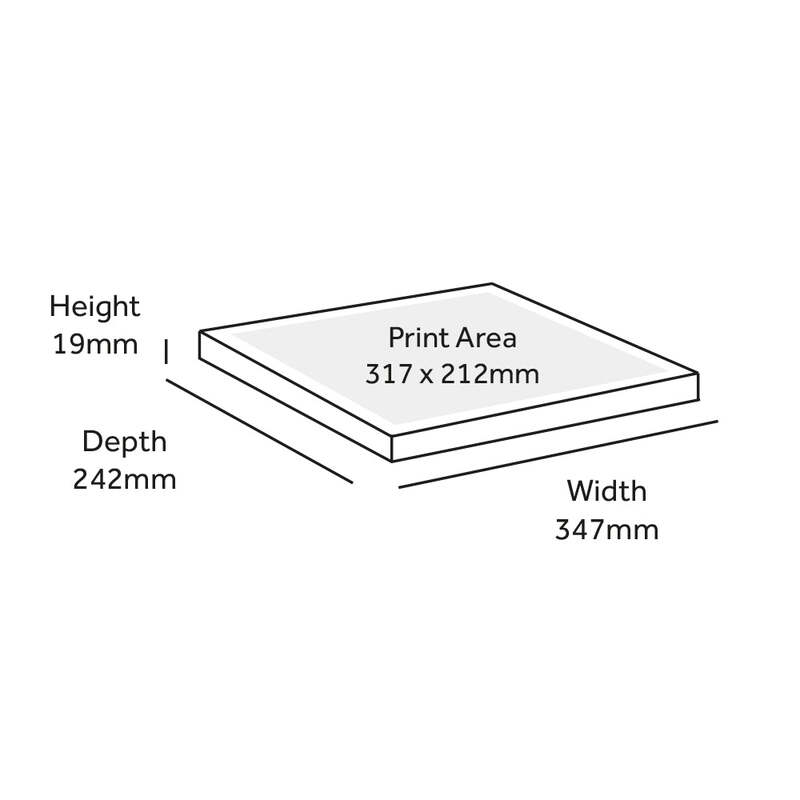

- Comparative Table: Manufacturer & Technical Specifications

- Customization: Unlocking Branding Potential with Logo Print

- Design & Production Workflow for Personalised Sheets

- Applications: Case Studies and Industry Impact

- Conclusion: Printed Greaseproof Paper Sheets in Modern Branding

(printed greaseproof paper sheets)

Introduction to Printed Greaseproof Paper Sheets

Printed greaseproof paper sheets have revolutionised the way food businesses package, protect, and present their offerings. Combining functional benefits with significant branding opportunities, these sheets are no longer just a wrapping solution—they are an essential element in modern marketing and customer experience. With rising consumer awareness around hygiene, sustainability, and aesthetics, demand for greaseproof paper sheets with logo has soared across the foodservice sector. Global packaging market reports reveal that by 2023, the demand for sustainable food packaging grew by 17%, while bespoke printed solutions accounted for 32% of all new product launches in the bakery and QSR (quick-service restaurant) categories. This surge reflects the dual need for practicality and impactful communication, a niche perfectly filled by personalised greaseproof paper sheets.

The Rise and Innovation of Greaseproof Paper Solutions

The journey from generic, unbranded packaging to high-performing, customizable greaseproof sheets is driven by advancements in material science and printing technology. Traditionally, wax or paraffin papers sufficed as oil barriers. Modern greaseproof papers, however, utilise refined pulps and chemical-free processes to achieve natural oil resistance. Food safety compliance is critical; top-tier manufacturers now achieve Kit 7-8 grease resistance as per TAPPI standards, exceeding many governmental safety requirements.

Digital and flexographic printing methods have enabled full-colour logos, patterns, and novel finishes, while maintaining full recyclability and compostability. A 2022 industry survey showed that 41% of food brands switched to custom printed wraps specifically to improve customer perceptions of quality and hygiene. Manufacturers now deliver minimum order quantities as low as 10,000 sheets, making customisation accessible to independent outlets as well as international chains.

Comparative Table: Manufacturer & Technical Specifications

To guide purchasing decisions, below is a comparison table highlighting trusted suppliers, sheet options, eco-credentials, and printing abilities. This data is distilled from direct supplier specifications and recent procurement surveys.

| Manufacturer | Sheet Size Options | Material Composition | Grease Resistance (TAPPI Kit) | Logo Print Capability | Minimum Order Qty | Compostable/ Recyclable | Lead Time (days) |

|---|---|---|---|---|---|---|---|

| EcoWrap Printing | 25x35, 30x40, 40x60 cm | Unbleached Kraft | 7-8 | Full Colour Digital/Flexo | 10,000 | Yes / Yes | 12-16 |

| Papermill Solutions | 20x30, 28x38 cm | Chlorine-Free Bleached | 6-7 | Single/Two Colour Flexo | 20,000 | Yes / Yes | 14-21 |

| BrandWrap Europe | Custom Sizes | Wood-Free Greaseproof | 7 | Full Colour Offset | 8,000 | Yes / Yes | 10-18 |

| FoodPak Ltd | 15x20, 25x35 cm | Recycled Blend | 5 | Monochrome Flexo | 5,000 | Yes / Yes | 18-24 |

The table illustrates not only the range of technical standards but reveals the increasing availability of personalised, sustainable printed greaseproof options. All featured manufacturers comply with EU food contact regulations.

Customization: Unlocking Branding Potential with Logo Print

Incorporating logos and bespoke designs onto greaseproof paper sheets significantly enhances brand visibility, customer loyalty, and perceived product value. Research published in 2022 by Mintel found that 58% of fast-casual diners are more likely to recall a brand when served food with branded packaging.

The personalisation process is not merely cosmetic—ink types (water-based, food-safe), printing accuracy, and colour consistency are critical for food safety and cohesive branded experiences. Modern digital presses ensure photorealistic logo reproduction, while eco-certified inks support a business's sustainability claims. For businesses operating kiosks, bakeries, delis, or franchise models, printed greaseproof paper sheets

with logo become a cost-efficient tool in their marketing toolkit. Creative layouts such as QR codes or limited-edition graphics add further engagement possibilities, seamlessly integrating packaging into digital and loyalty strategies.

Design & Production Workflow for Personalised Sheets

The process of producing custom printed greaseproof paper sheets follows a series of controlled steps to ensure food safety, print clarity, and supply reliability. Typical workflow includes:

- Consultation & Material Selection: Companies work with packaging consultants to determine sheet sizes, material grade, and specific grease resistance required, depending on food types (burgers, pastries, wraps, etc.).

- Artwork Finalisation: Artwork is submitted in vector format to achieve sharp reproduction. Pre-production samples (digital proofs or physical dummies) enable feedback and colour calibration.

- Printing & Quality Assurance: Sheets are printed using high-speed flexographic or offset presses. Inspection protocols check for ink uniformity, misprints, batch consistency, and migration compliance.

- Cutting & Packing: Sheets are trimmed to specification and delivered in moisture-barrier packaging to maintain product integrity.

Applications: Case Studies and Industry Impact

The practical benefits and branding power of personalised greaseproof paper sheets are visible in a broad set of real-world applications. Consider the following case studies:

- Artisan Bakeries: A leading London-based bakery chain introduced custom white greaseproof paper sheets with pastel logo print, resulting in a 39% increase in Instagram mentions in one quarter, directly linked to visually appealing takeout packaging.

- Multi-Site QSR: A European premium burger franchise adopted 30x40cm printed sheets in both dine-in and delivery, reducing wrapper replacements for grease leaks by 23%, and reporting improved customer feedback scores on presentation.

- Event Catering: Corporate caterers use personalised greaseproof paper sheets in branded lunchboxes to reinforce the client's image and enhance the perceived value of event catering offers. Post-event feedback cited a “professional touch” on 62% of survey responses.

Conclusion: Printed Greaseproof Paper Sheets in Modern Branding

As the competitive landscape intensifies, food businesses need to deliver on hygiene, sustainability, and memorable visual identity all at once. Printed greaseproof paper sheets, and their tailored derivatives such as logo-printed and personalised greaseproof paper sheets, represent a powerful intersection of these demands. Through validated technical enhancements, sustainable material commitments, and adaptable customisation, this product line has become an essential asset in food packaging strategies worldwide. For any operation seeking to elevate its packaging and brand image while upholding environmental stewardship and food safety, investing in high-quality, custom printed greaseproof paper sheets is a decisive step forward.

(printed greaseproof paper sheets)