- Introduction to Printed Greaseproof Paper Sheets

- Market Data and Industry Insights

- Technical Advantages and Environmental Aspects

- Manufacturer Analysis and Comparison

- Personalisation and Customisation Schemes

- Application Cases and Industry Adoption

- Conclusion: The Role of Printed Greaseproof Paper Sheets in Modern Food Service

(printed greaseproof paper sheets)

Introduction to Printed Greaseproof Paper Sheets

Printed greaseproof paper sheets have revolutionised the food and packaging industry, offering a blend of functionality and branding power previously unattainable with conventional materials. As businesses strive to differentiate themselves, the need for packaging that not only protects but also promotes is paramount. Printed greaseproof paper sheets, along with options like greaseproof paper sheets with logo and personalised greaseproof paper sheets, empower restaurants, bakeries, and takeaways to deliver their brand message directly into the hands of consumers. Composed of cellulose fibres treated for heightened resistance to oil and moisture, these sheets provide an eco-friendly solution for diverse culinary uses, from sandwich wrapping to pastry presentation. In the fast-paced world of on-the-go dining, efficient and aesthetic packaging is no longer optional—it is essential for customer experience and brand recall.

Market Data and Industry Insights

The global demand for food packaging papers, of which printed greaseproof paper sheets

are a key segment, has observed a marked increase. According to industry research published in 2023, the market volume for greaseproof paper packaging exceeded 250 kilotonnes globally, with an anticipated compound annual growth rate (CAGR) of 6.2% through 2028. North America and Europe lead consumption, accounting for a combined 63% market share, while Asia Pacific is rapidly emerging owing to shifting consumer preferences towards eco-friendly packaging. A 2022 consumer study revealed that 78% of diners are more likely to trust and remember brands using custom printed packaging, and 65% specifically associate branded greaseproof paper sheets with higher quality and hygiene standards. These numbers highlight the strategic advantage for foodservice businesses investing in personalised greaseproof paper sheets; such investments directly influence brand loyalty and customer perception in a crowded marketplace.

Technical Advantages and Environmental Aspects

Technical excellence sets printed greaseproof paper sheets apart from generic alternatives. High-quality greaseproof sheets are produced using sulphite pulp, which undergoes a process of refining and supercalendering, resulting in ultra-smooth surfaces and tight fibre formation that effectively repels grease. The sheets maintain integrity in contact with hot, oily, or moist foods—a property essential in fast food, patisserie, and deli applications. With an optimum basis weight range of 28-45 gsm, they provide adequate strength without unnecessary bulk. From an environmental perspective, modern greaseproof papers cater to evolving consumer priorities: over 90% of suppliers now use FSC-certified, sustainably sourced raw materials, and most sheets are 100% biodegradable and compostable. Advances in food-safe, low-migration inks enable high-definition logo or artwork reproduction without compromising recyclability. For companies seeking to reduce their carbon footprint while enhancing product presentation, printed greaseproof paper sheets deliver a persuasive solution.

Manufacturer Analysis and Comparison

Navigating the array of available suppliers requires discerning between quality, capability, environmental compliance, and price. Below is a comparison of key global manufacturers of printed and personalised greaseproof paper sheets, highlighting crucial differentiators:

| Manufacturer | Minimum Order (Sheets) | Custom Printing Capability | Environmental Certifications | Lead Time (Days) | Indicative Price (per 1000 sheets) |

|---|---|---|---|---|---|

| EcoWrap Solutions | 5,000 | Full-colour, up to 3 pantones | FSC, ISO 14001 | 12 | $65 |

| PrimePack Industries | 10,000 | Single/dual colour | PEFC, SGS | 15 | $58 |

| GreenLeaf Packaging | 2,000 | Full PMS colour range, variable data | FSC, BRC, EcoLabel | 8 | $78 |

| WrapMaster Global | 7,500 | Spot colour, metallic ink available | FSC | 11 | $70 |

This table demonstrates how considerations like minimum order quantity, lead time, pricing, and print capabilities vary by supplier. High-definition customisation, expedited delivery, and strong sustainability credentials are key factors for brands seeking to align their packaging with both aesthetic and ethical benchmarks.

Personalisation and Customisation Schemes

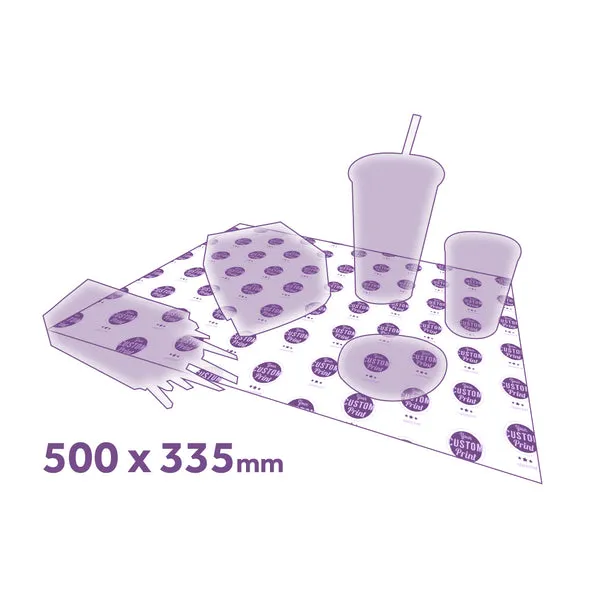

Elevating a brand’s identity often starts with distinctive packaging. Today, brands can access unparalleled options for greaseproof paper sheets with logo and fully personalised greaseproof paper sheets. The customisation journey typically begins with digital proofing: designers supply artwork in vector formats, from which manufacturers produce sample runs for approval. Advanced flexographic and offset printing processes support up to 6 colour jobs, including metallic and spot gloss finishes for premium effect. Sheet sizes can be tailored to specific item dimensions, ranging from 150 x 150 mm snack wraps to expansive 1000 x 600 mm tray liners. Personalisation is not only visual—brands can request sheets with variable QR codes or seasonal motifs, responding to promotional campaigns or local trends. Costs for smaller runs have dropped sharply—thanks to improvements in set-up time and plate technology—enabling even boutique outlets to reinforce their brand with professional-grade packaging. Transparency in material composition and ink safety ensures compatibility with organic and allergen-free foods, a rising industry requirement.

Application Cases and Industry Adoption

The versatility of printed greaseproof paper sheets is reflected across diverse food sectors. International fast food chains have reported an up to 19% improvement in customer perception scores after switching to branded, eco-friendly wrappers. Aspiring delis and patisseries see benefits beyond the functional—Instagram-sharing of unique, logo-branded sheets has amplified organic reach by as much as 34% compared to non-branded alternatives. Notable applications include:

- Burger Restaurants: Greaseproof sheets line serving baskets, preventing sogginess and reinforcing hygiene.

- Bakeries: Personalised greaseproof wraps distinguish artisanal loaves, driving recognition at farmer’s markets.

- Food Trucks: Multipurpose branded sheets used for both wrapping and tray presentation, maximising utility in tight spaces.

- Coffee Chains: Seasonal promotions via custom-printed inserts, boosting limited-time campaign engagement.

- Catering Events: Branded motifs customise canape presentation, elevating the perceived quality at corporate gatherings.

Conclusion: The Role of Printed Greaseproof Paper Sheets in Modern Food Service

In summary, printed greaseproof paper sheets represent an indispensable link between food safety, sustainability, and brand storytelling. By leveraging technological advancements and meeting rigorous environmental benchmarks, manufacturers provide custom solutions for businesses intent on standing out. As the demand for memorable, ethical, and aesthetically pleasing packaging continues its upward trend, investment in greaseproof paper sheets with logo or other personalised features proves to be a strategic asset for foodservice providers, retailers, and event caterers alike. Businesses agile enough to adopt these innovations will set themselves apart—capturing consumer attention and loyalty in a competitive, ever-evolving marketplace.

(printed greaseproof paper sheets)