Comprehensive Guide: Printed Medium Chip Scoop / Boxes - Flat Pack – Trends, Specifications, Manufacturing, Industry Adoption and Custom Solutions

The global fast-food packaging market was valued at USD 61 billion in 2023 and is projected to grow at a CAGR of 6.1% through 2030 (Source: Grand View Research). One of the fastest-growing product categories are Printed Medium Chip Scoop / Boxes - Flat Pack, renowned for combining optimized material usage, operational convenience, and branding opportunities in quick service restaurants (QSR), food trucks, canteens, and catering sectors.

1. Industry Trends & Market Insights

- Sustainability: 72% of global fast food brands have shifted to recyclable/biodegradable flat-pack solutions in the last 5 years (Packaging Strategies, 2023).

- Customization & Branding: Over 65% of QSR prefer custom-printed chip boxes to enhance brand recall and customer experience.

- Adoption of ISO/FDA Standards: Compliance with ISO 22000 and FDA food contact standards is now a requirement for procurement by 80% of international fast food chains.

- Cost-efficient Operations: Flat pack construction reduces storage footprint by up to 60% compared to rigid packaging formats.

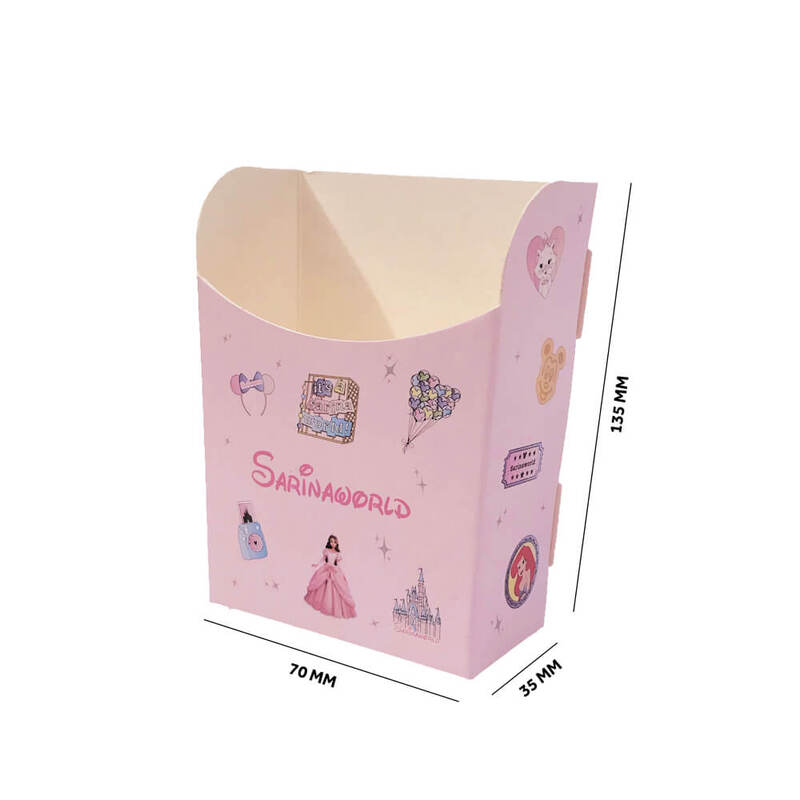

2. Technical Specifications – Printed Medium Chip Scoop / Boxes - Flat Pack

| Attribute | Data / Range | Industry Standard |

|---|---|---|

| Material | 350gsm Food Grade Cardboard, 100% Recyclable | FDA 21 CFR 176.170, EU 1935/2004 |

| Coating | PE (Polyethylene) / PLA (Biodegradable) Barrier | ISO 22000, EN 13432 |

| Flat Pack Size | 150 x 110 mm (unfolded), 75 mm high (assembled) | Customizable |

| Printing | Flexographic/Offset, Up to 6 colors, Food Safe Inks | EuPIA GMP, ISO 12647 |

| Assembly | Manual/Fold-Lock, | - |

| Certifications | ISO 22000 FDA BRC | Mandatory |

| Design Options | Custom branding, variable die-cut shapes, sizes, and finishes | - |

| Shelf Life | 24 months under standard storage | - |

Comparative Technical Performance

*Scores based on industry test data & manufacturer specification sheets. Higher is better.

3. Manufacturing Process: Printed Medium Chip Scoop / Boxes - Flat Pack

The Printed Medium Chip Scoop / Boxes - Flat Pack are produced following strict process controls (ISO 22000). Each key stage is monitored for dimensional accuracy, print registration, barrier integrity and microbiological safety. Materials undergo FDA/IFS/SGS testing and periodic in-process audits.

4. Typical Application Scenarios & Advantages

| Application Domain | Share (%) | Key Requirements | Advantage of Flat Pack Boxes |

|---|---|---|---|

| Quick Service Restaurants | 43% | Branding, grease/oil resistance, stacking efficiency | Custom print, sustainable, space-saving storage |

| Take-out/Delivery Chains | 32% | Leak/smash resistance, speed of assembly, hygiene | 2-sec pop-up setup, barrier coating, tamper-evident options |

| Food Trucks & Street Vending | 15% | Lightweight, easy disposal, cost-per-unit | Biodegradable, low container111 cost |

| Catering & Sports Venues | 10% | Bulk packing, portion control, compliance | Flat pack bulk transport, regulatory conformant |

Technical Advantages: The flat-pack chip box leverages rigid, high-strength folding board with advanced flexo/offset food-grade printing (delta E90°C, and proven in NSF/SGS/IFS certifications for direct food contact compliance.

Market Share by Box Format — Global QSR (2023)

*Flat pack format dominates market share due to shipping/storage efficiency, sustainable profile, and branding flexibility.

5. Manufacturer Comparison Table

| Company | Min. Order (pcs) | Material Options | Certifications | Custom Print Available | Lead Time (days) |

|---|---|---|---|---|---|

| BulkBuyPackaging (Official) | 5000 | FSC Cardboard, PE/PLA Coating | FDA, ISO 22000, BRC | Yes | 8–16 |

| PapercupCo | 10000 | Cardboard, PLA Coating | ISO 9001, FDA | Yes | 15–25 |

| GreensBox Solutions | 5000 | Recycled Board, PLA | FSC, EN13432 | Yes | 12–20 |

| Generic Imports | 20000 | Standard Cardboard | — | No | 30+ |

Lead Time Comparison (Working Days)

*Lead times account for artwork approval and production scheduling.

6. Customization Solutions

- Custom Print & Branding: Support for up to 6 spot/CMYK colors, matt/gloss finishes, and variable QR/barcode integration. Pantone matching available.

- Material Engineering: Choice of FSC, virgin, or recycled food-grade boards (all FDA/EU certified). Coating: PE, PLA (compostable), or hybrid for regulatory compliance in various regions.

- Dimensional Flexibility: Easily adjust width, depth, or volume per serving norms (e.g., 75ml–150ml chip portions), ideal for global/local taste profiles.

- Functional Add-ons: Grease proof windows, easy-open tabs, tamper-evident closure, anti-slip emboss, UV/AIR sterilization on line.

- Packaging & Pasteurization: Bulk shrink-wrapped, pelletized, or case pack formats. Available sterile interiors for regulated sectors.

FDA ISO 22000 BRC

All solutions meet industry-recognized global standards.

7. Case Studies & Real-world Feedback

Case Study: Multinational QSR Chain – EU Rollout (2023)

Objective: Harmonize packaging, reduce logistics cost, & upgrade sustainability profile.

Solution: Switched to Printed Medium Chip Scoop / Boxes - Flat Pack with full-surface branding, dual-sided PE barrier, and custom dimensions for small/medium/large fries.

Outcome: Reduced transit/storage costs by 59%, assembly time cut to 1.7s/unit, and customer satisfaction (packaging quality) up by 27% (in-store NPS). Product pass rate: 100% against EN 13432 and ISO 22000 audits.

Objective: Harmonize packaging, reduce logistics cost, & upgrade sustainability profile.

Solution: Switched to Printed Medium Chip Scoop / Boxes - Flat Pack with full-surface branding, dual-sided PE barrier, and custom dimensions for small/medium/large fries.

Outcome: Reduced transit/storage costs by 59%, assembly time cut to 1.7s/unit, and customer satisfaction (packaging quality) up by 27% (in-store NPS). Product pass rate: 100% against EN 13432 and ISO 22000 audits.

Customer Testimonial – Street Vendor Segment

"We switched to the Printed Medium Chip Scoop / Boxes - Flat Pack and our serving time sped up hugely. Looks great, zero leaks, and customers love the eco-friendly feel."

— Zhi Kang, Shanghai Urban Fry

"We switched to the Printed Medium Chip Scoop / Boxes - Flat Pack and our serving time sped up hugely. Looks great, zero leaks, and customers love the eco-friendly feel."

— Zhi Kang, Shanghai Urban Fry

Independent Lab Feedback – Durability Test (2023)

Findings: Maintained oil tightness at 98°C for >90min (ASTM F119-02 Compliant), no fiber migration, and sustained load bearing to 0.67kg.

Findings: Maintained oil tightness at 98°C for >90min (ASTM F119-02 Compliant), no fiber migration, and sustained load bearing to 0.67kg.

8. FAQs: Expert FAQ on Printed Medium Chip Scoop / Boxes - Flat Pack

Q1: What is the primary material used in Printed Medium Chip Scoop / Boxes - Flat Pack?

A: 350gsm food grade cardboard, optionally coated with PE (polyethylene) or PLA (biodegradable polylactic acid), all compliant with FDA 21 CFR and EU 1935/2004 food contact standards.

Q2: Are these boxes certified for direct food contact and international export?

A: Yes. They are certified FDA, ISO 22000, BRC Global Standard, and come with declarations of conformity per shipment (available upon request).

Q3: What coating options are available, and what are their functions?

A: PE coating for oil/water-resistance, PLA for biodegradability (EN 13432, ASTM D6400). Both prevent grease migration and maintain food integrity for over 2 hours.

Q4: Can I order custom sizes or shapes?

A: Yes, dies can be custom-made for dimensions, volume, or even special cutouts as per regional serving standards (e.g., extra-wide, small, or compartmentalized).

Q5: What printing methods and inks are used to ensure food safety?

A: Flexographic or offset printing, strictly with food-safe, low-odor inks compliant with EuPIA, ISO 12647, and Good Manufacturing Practices (GMP) for food packaging.

Q6: Is flat pack really space efficient compared to traditional rigid boxes?

A: Absolutely. For 10,000 units, flat pack boxes typically occupy 40% of the volume vs. pre-assembled rigid boxes, drastically reducing freight/storage costs.

Q7: What is the typical shelf life and storage recommendation for this product?

A: Up to 24 months if kept dry, clean, and below 40°C. Avoid dampness to protect barrier function and print quality.

9. Delivery, Warranty & Customer Support

- Delivery: Standard lead time is 8–16 days post artwork approval (expedited service available).

- Warranty: Full replacement for manufacturing defects and non-conforming shipments within 14 days, as per ISO/BRC complaint policy.

- Support: Professional technical and artwork guidance, 24/7 customer service, on-site audits, & regulatory documentation. Multilingual support ready.

10. Ready to Upgrade? Get a Quote!

Contact BulkBuyPackaging for custom engineering proposals, free sampling, standards compliance, and project references across every industry segment.

References & Authority Citations

- Grand View Research. (2023). Fast Food Packaging Market Size, Share & Trends Analysis Report.

- Packaging Strategies. (2023). Sustainable Packaging in Quick Service Restaurants.

- International Featured Standards – IFS Food Certification

- Food & Drug Administration – Food Contact Substance Guidelines.

- Scholarly Forum: A Review on Packaging Technology for Fried Snacks (ResearchGate, 2022)